Last Updated on September 7, 2023 by Pro Handyman Australia – Editorial Team

Understanding the Significance of Air Filters

Air filters are integral to the maintenance of indoor air quality. Their primary function in homes revolves around furnace filters, which ensure the coils and heat exchanges of the heating and air conditioning system remain uncontaminated. A buildup of debris on these components forces the system to expend more energy, which can lead to wear and tear. Therefore, consistently ensuring your air filter is clean not only enhances your home’s air quality but also extends the lifespan of your heating and air conditioning unit.

The Role of Air Filters in Health and Well-being

The filter you select for your heating and air conditioning unit significantly influences the air quality within your living space. Numerous factors determine the amount and type of particles present in indoor air, including the number of occupants, pets, and the various activities that take place within the home. Those with health conditions such as allergies or asthma should be particularly mindful about maintaining pristine air filters. Different air filters are equipped to trap a variety of pollutants, from dust mites, mold spores, and pet dander to smoke, bacteria, and pollen. Therefore, your filter’s ability to trap these particles can have a direct impact on your health.

Navigating Air Filter Efficiency Ratings

To identify the most suitable air filter for your residence, understanding its efficiency is crucial. The industry standard for measuring air filter efficiency is through the Minimum Efficiency Reporting Value (MERV). However, some brands have their distinct measuring systems, such as the Microparticle Performance Rating value (MPR) by Filtrete, which claims to capture even finer particles surpassing regular industry standards. Typically, air filters with higher MERV and MPR ratings are more efficient in trapping pollutants.

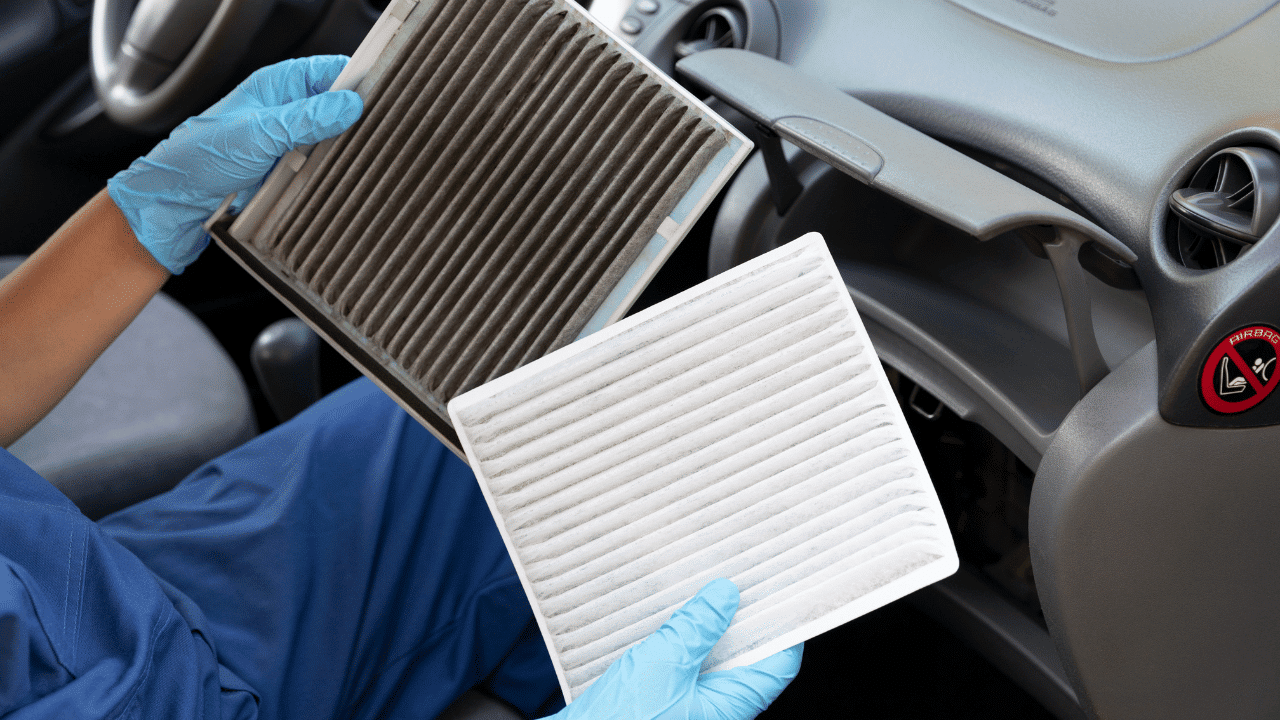

Maintaining Your Air Filter

Consistent maintenance is pivotal for the optimal functioning of air filters. Regardless of the quality of the filter, its efficiency diminishes when it’s laden with pollutants. For optimal performance and air quality, it’s generally advised to replace your air filters every month. However, specific circumstances like a new house or ongoing home renovations might necessitate more frequent replacements due to increased dust and particulate presence.

Air Filter Varieties: Dimensions and Design

Before committing to a new air filter, it’s crucial to determine the correct size your system requires. This can be done by referring to the dimensions mentioned on your existing filter. While most filters designed for residential HVAC systems possess a thickness of 1 inch, larger homes with an extensive air circulation might need filters up to 4 inches thick. Fortunately, for unconventional ventilation openings, adjustable filters can be sourced. There are also extended filter sizes tailor-made for room air conditioners, register vents, and return vents located in the floors, walls, and ceilings.

Beyond just size, air filters are available in various materials and styles. The filter’s efficacy is influenced by the dimensions and density of the material it’s made from and the size and volume of the particles it’s designed to filter. Basic, less costly filters typically consist of a fibrous layer that captures rudimentary particles. However, for more comprehensive filtration, filters with elevated MERV/MPR ratings are preferable. For example, pleated filters boast higher efficiency owing to their increased surface area. Many of these filters also come with an electrostatic charge, enabling them to attract and retain minuscule particles. There are also reusable filters in the market, crafted from materials that can be easily cleaned with water.

Home Air Purifiers: A Deep Dive

Home air purifiers have witnessed a surge in popularity, primarily due to growing concerns surrounding air pollution. These devices are designed to refine indoor air by eliminating potential pollutants, allergens, and toxins.

The spectrum of pollutants eradicated hinges on the purifier type. While certain purifiers are equipped with filters that trap particles as air traverses through them, others disperse air particles without preliminary filtration. Nevertheless, to ensure maximum effectiveness, it’s advisable to pair air purifiers with routine cleaning activities such as dusting, vacuuming, and sweeping. This combined approach aids in eradicating detrimental particles more comprehensively.

When it comes to selecting an air purifier, size plays a pivotal role. Opting for a larger system can be advantageous if your objective is to purify the air in an expansive space or the entire house. Conversely, compact units, ideal for individual rooms, might be particularly beneficial for individuals grappling with respiratory conditions like asthma.

Air Filter Testing Process

In our specialized testing room, isolated from the building’s general heating, cooling, and ventilation systems, we meticulously examine HVAC filters. This room, with its unique air circulation duct, has both its temperature and humidity levels carefully monitored. Prior to each experiment, we ensure the air within this space is pristine.

To challenge these filters, we introduce a concoction of varied particle-sized dust and standardized research cigarette smoke into the room. After achieving the desired deteriorated air quality for our examination, we initiate the room’s air circulation. Utilizing a particle analyzer, we gauge the filter’s speed in decreasing the particle count. We’re equally attentive to the airflow restriction each filter introduces, which we measure using a differential pressure transducer placed across the filter.

Our findings? The cream of the crop excel at trapping pollutants without compromising airflow, ensuring optimal operation of heating and cooling systems. However, subpar models disappoint either by capturing minimal pollutants, significantly impeding airflow, or both. An additional consideration for consumers is the annual replacement cost. While we base our calculations on the assumption of a singular filter requirement and manufacturer-recommended replacement frequency, remember that bulk purchases might offer savings.

Deciphering HVAC Filtration: The MERV Rating Explained

The HVAC filter industry gauges performance via the MERV scale (Minimum Efficiency Reporting Value), a spectrum ranging from MERV 1 through MERV 16. While some sources suggest it extends to MERV 20, updated testing standards affirm MERV 16 as the upper limit.

At the scale’s commencement, filters—usually crafted from fiberglass or mesh—primarily ensnare large particles such as hair, fabric fibers, and some pollen variants, with disposable fiberglass filters setting you back a mere $2. As the rating advances, the capability to seize smaller particles amplifies, as does the price tag. By MERV 8, filters usually transition to pleated media, constructed from materials like fiberglass paper, polyester, and plastic, ensuring effective capture of pollen, mold spores, and various household dust.

Achieving MERV 13, which is the pinnacle for the majority of popular residential HVAC filter dimensions, means the filter is adept at halting bacteria, smoke, and other minuscule particles. Such proficiency comes with a price, often exceeding $40.

While most home enhancement outlets stock filters within the MERV 1 to MERV 13 spectrum, there are filters with higher MERV ratings that could potentially challenge residential HVAC systems. It’s worth noting that some brands and retailers introduce alternative scales, such as Home Depot’s Air Filter Performance Rating (FPR) system. Regardless, the MERV rating typically remains visible on product packaging or descriptions.

While certain manufacturers promote their filters as “allergen” specific, this usually implies a rating of MERV 11 or above, competent in capturing most common allergen-sized particles. Essentially, there’s nothing distinctly anti-allergenic about these filters; others with analogous MERV ratings should perform similarly.

MERV versus HEPA: A Comparison

Predominantly, the MERV standard evaluates filters designed for forced-air HVAC systems. Conversely, HEPA (high-efficiency particulate air) standards are considerably more stringent. The intricacy of HEPA filtration often results in considerable airflow restriction, rendering them unsuitable for most residential forced-air setups. Typically, HEPA filters find their home in air purifiers and vacuum cleaners.

Selecting the Ideal Replacement Air Filter

While the straightforward approach to replacing an air filter involves repurchasing your current filter model, there are alternatives if the exact model isn’t accessible or if you seek a more cost-effective or high-performance variant. With air filters available in several standard dimensions and adaptable designs for diverse filter-box or return-air openings, choosing the right one necessitates careful consideration.

Determining the Correct Filter Size

Your starting point involves locating your present filter. Often, HVAC filters are situated adjacent to your furnace or air handler. Alternatively, some systems house filters within return air ducts distributed throughout various rooms (characterized by grates that reintake air).

Upon locating the filter, assess its dimensions in terms of length, width, and depth. A filter that doesn’t sit snugly or misaligns with its gaskets might not be the right fit. For those that fit perfectly, note the size displayed on the filter frame or capture an image. Should you remain uncertain about the size, refer to your equipment’s manual or contact its manufacturer.

While local hardware stores usually stock standard sizes, occasionally, you might have to resort to online vendors. And if you’re trying to deduce the size while standing in a store aisle, be cautious. With a multitude of common dimensions, there’s a high probability of erring in your guess.

The thickness of the filter, usually 1 inch or increasingly 4 inches, plays a pivotal role in subsequent choices.

Making an Informed Filtration Decision

Every pleated HVAC filter is designed to enhance indoor air quality by trapping dust, pollen, and minute particles, functioning silently yet efficiently. However, a filter too dense can hinder efficient heating and cooling, potentially leading to long-term equipment damage from parts overheating or freezing.

Conversely, an overly porous filter is equally detrimental, missing out on enhanced air purification and risking HVAC equipment damage due to accumulated debris. Striking the right balance entails selecting a filter that ensures consistent airflow whilst maximizing debris capture.

For those with a filter of 1-inch thickness, high MERV ratings might pose airflow restrictions for certain systems. While tests have shown some high-MERV filters (MERV 11 and above) effectively maintain airflow, they tend to be pricier. Conversely, filters with optimal airflow ratings typically have lower MERV ratings, are more affordable but might not excel in particle-capture tests.

For precise airflow requirements of your HVAC system, measuring the static pressure is vital. Engaging a skilled technician, equipped with basic tools, can swiftly gauge this, particularly during a routine system tune-up. They can then provide expert recommendations on suitable filters. If obtaining a measurement isn’t feasible, many professionals advocate for a MERV 8 pleated filter as a universally effective choice. These filters, while cost-effective, surpass basic fiberglass filters in debris capture.

For those with 4-inch or thicker filters, even high-MERV filters should seamlessly integrate with your HVAC system. Their superior debris capture capability, courtesy of their expansive surface area, ensures efficient air purification without compromising airflow. At this thickness, a MERV 13 offers a commendable balance between air quality enhancement and affordability.

For homes equipped with 1-inch filters, contemplating an upgrade to accommodate 4-inch filters can be worthwhile. This entails adding a compact cabinet beside your furnace or air handler, a modification that’s affordable.

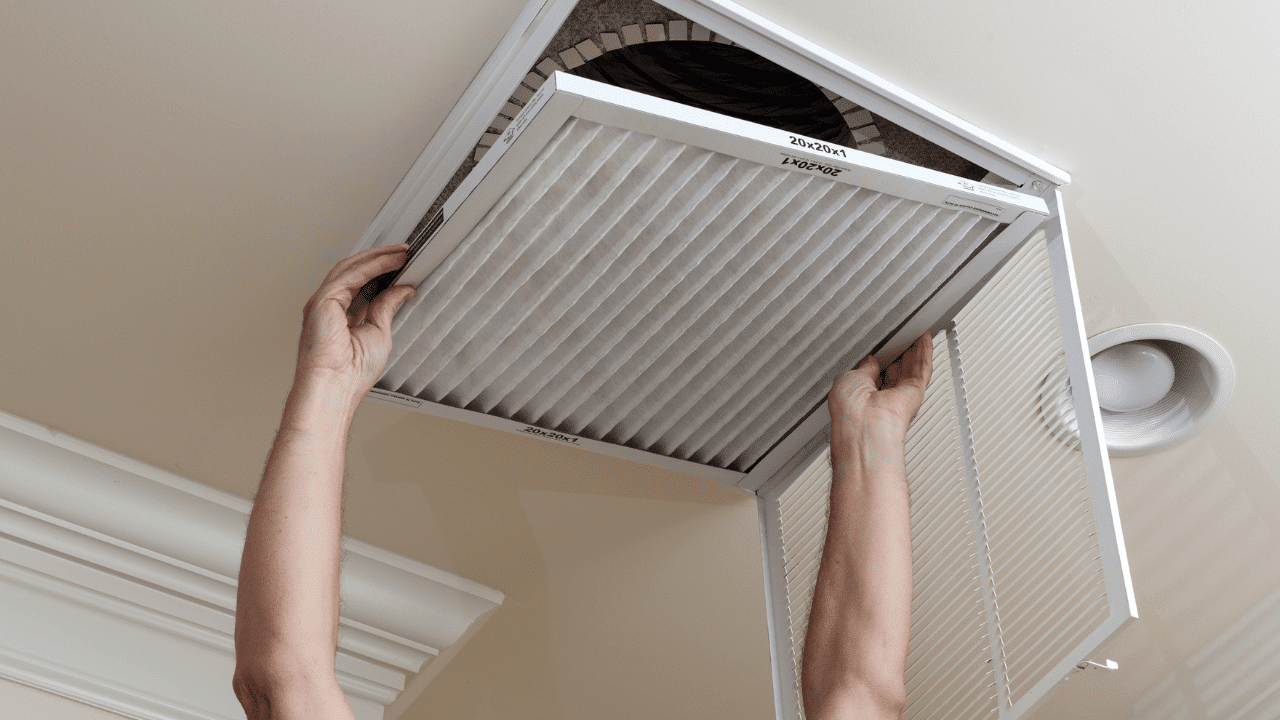

Installing the Replacement Filter

While certain systems may require basic tools like screwdrivers or pliers for filter access, many designs allow for easy replacement. This often involves smoothly extracting the old filter and replacing it with the new one in the designated slot. Ensure the filter’s correct orientation by observing arrows on the frame indicating airflow direction.

The Pinnacle of HVAC Filters: Understanding Your Choices

As the quest for energy-efficient solutions in homes and industries rises, HVAC filters have evolved. Below are a few elite options available in the market today, along with their unique attributes and application areas.

High-Efficiency Pleated Filters: The Standard Choice

Traditionally preferred in most HVAC systems, High Efficiency Pleated Filters stand out due to their ease of installation, standard dimensions, and affordability. Distinct from regular flat filters, these feature an accordion-folded media, which facilitates a more extensive surface area and minimizes airflow resistance. You can find them in either standard pleats or mini-pleats with MERV ratings spanning from 11 to 14.

Advantages:

Energy Conservation and Eco-friendliness: Pleated filters, thanks to their low airflow resistance, are ideal for projects demanding high efficiency paired with a minimal initial pressure drop. Many of these filters qualify as Environmentally Preferable Products (EPP), suggesting that they impose a reduced impact on human health and our environment compared to alternative products.

Common Uses: Commercial spaces, healthcare establishments, municipal structures, governmental facilities, the hospitality sector, and residences.

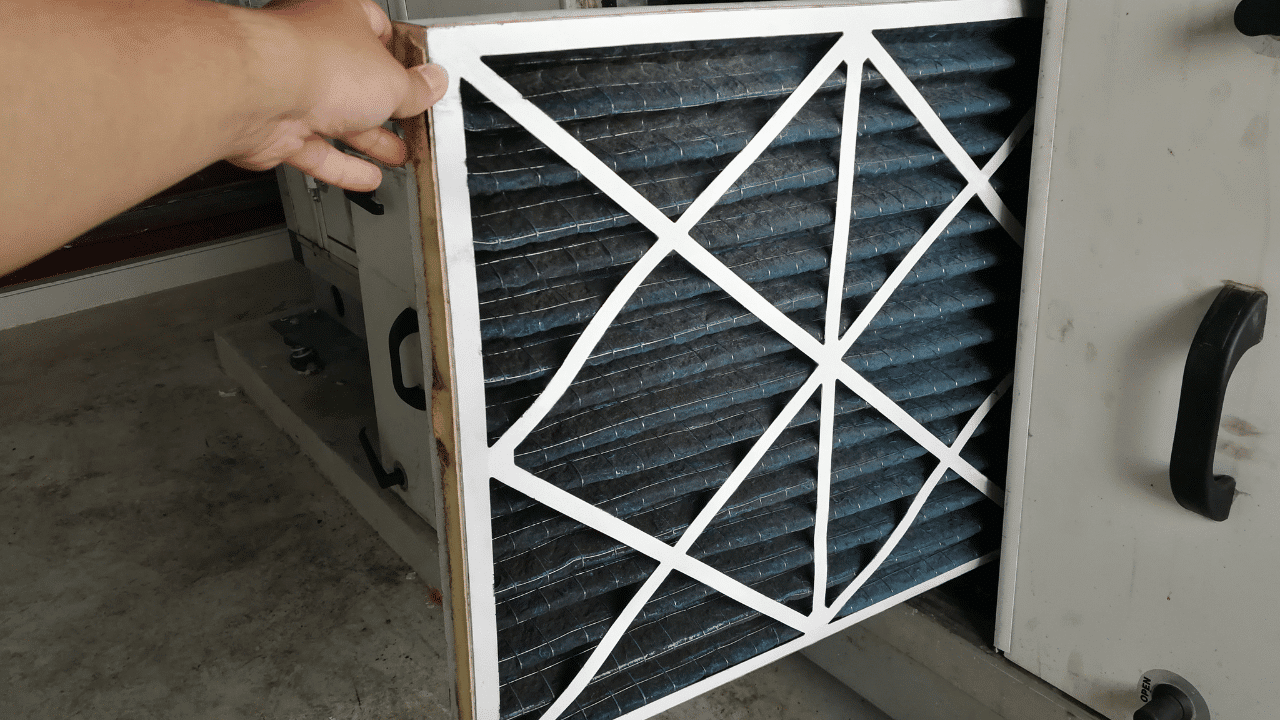

Rigid Cell Filters: The Sturdy Alternative

Taking on a box-like design, Rigid Cell Filters utilize either synthetic media or fiberglass. However, synthetic media is more favored due to the potential of fiberglass fibers to mix with the airflow. These filters, resembling pleated ones in appearance but deeper, often come encased in frames made of galvanized metal or plastic. They boast up to 95% efficiency with MERV ratings from 11 to 14.

Advantages:

Robustness: Thanks to their galvanized steel frames and additional diagonal supports, Rigid Cell Filters withstand challenging conditions, such as variable air volume, without compromising their performance.

Common Uses: Commercial and industrial HVAC systems, high-humidity environments, clean rooms, healthcare, food services, and manufacturing.

Pocket Filters: The Commercial Go-to

Named for their distinctive construction, Pocket Filters or Bag Filters feature media pockets, often 10”-36” deep, secured within plastic or galvanized steel frames. Typically employed as final filters in commercial settings or as preliminary filters in medical establishments, these filters can reach up to 95% efficiency with MERV ratings peaking at 14.

Advantages:

Extended Operational Life: Offering a long-lasting service life, Pocket Filters consistently maintain low pressure drops, spanning over 8,000 hours. This lifespan can be further augmented when paired with a pre-filter.

Common Uses: Commercial establishments, educational institutions, healthcare centers, governmental buildings, and manufacturing units.

HEPA Filters: The Ultimate in Efficiency

Reserved for environments where potential hazards from biological, chemical, or radioactive particles exist, HEPA Filters also find applications in residential, industrial, and commercial settings. To earn the HEPA classification, filters must adhere to the standards outlined by the U.S. Department of Energy and undergo regular testing for efficiency and performance. Notably, these filters aren’t MERV rated because their exceptional performance exceeds conventional standards, filtering at least 99.97% to 99.99% of particles sized 0.3 microns.

Advantages:

Unmatched Efficacy: The unique trait of HEPA filters is their enhanced efficiency with prolonged usage. As they accumulate dirt, their particle filtering ability improves. This enhancement results from a process called impaction, where particles larger than the gaps between fibers become embedded on the filter, making it increasingly efficient.

Common Uses: Laboratories, clean rooms, medical facilities, aircraft, residences, among others.

The Significance of Pressure Drop in HVAC Systems

The term ‘pressure drop’ denotes the difference in air pressure immediately before and after your filter. When the pressure drop is high, it indicates a substantial resistance to airflow, leading to a significantly lower air pressure on the filter’s output side compared to its intake.

Although a system might initially display a high resistance, the pressure drop can decrease over time as the air pressure accumulates on the filter’s intake side, achieving equilibrium in the system. However, this equilibrium doesn’t come without consequences. It compels the HVAC system to exert more, extending its operating duration and causing potential wear and tear, which can be energy-consuming.

It’s crucial to monitor pressure drop because prioritizing efficiency without considering pressure drop can lead to a surge in energy usage and expenses. Furthermore, it can result in polluted air circulation, risking system malfunctions and deteriorated HVAC performance due to diminished airflow.

Life Cycle Costing: Beyond the Price Tag

While a low-priced filter might seem like an economical choice at first glance, life cycle costing is a method that unveils the actual cost of ownership for a filter. This costing model encompasses three essential factors: the initial investment combined with maintenance, energy consumption, and disposal costs.

Initial Investment and Maintenance: Constituting approximately 18.5% of a filter’s operational cost, the initial investment includes the filter’s price, potential shipping damages or losses, storage fees, and labor expenses associated with its installation and upkeep.

Energy Consumption: This is the cornerstone of the life cycle cost, accounting for a whopping 81% of the total. Thus, opting for a high-efficiency filter with minimal initial resistance can be beneficial in mitigating pressure drop. Consequently, this leads to cleaner air circulation and decreased operating costs.

Disposal: Representing the smallest fraction at only 0.5%, disposal costs involve the labor required to discard or incinerate a used filter.

Given that energy consumption dominates the life cycle cost, the initial allure of a cheaper filter may be misleading. A pricier yet more efficient filter can contribute to energy savings. Such high-efficiency filters might also necessitate fewer maintenance checks. The savings from even a single filter change in a year can be significant, especially if there are multiple filters involved. Over time, when factoring in the escalating costs of energy and labor, the savings can be substantial.

Conclusion

The decision to choose an HVAC filter should not be based solely on initial costs. By understanding the nuances of pressure drop and incorporating life cycle costing into the decision-making process, homeowners and businesses can make informed choices that not only ensure clean air but also result in long-term savings and optimal system performance.