Last Updated on October 21, 2023 by Pro Handyman Australia – Editorial Team

Woodworking safety transcends mere guidelines—it’s a foundational principle, pivotal for both beginners and adept professionals alike. A woodworking shop isn’t just a sanctuary for creativity and craftsmanship; it’s also a space where collaboration fosters a collective responsibility towards safety. Ensuring that everyone within the vicinity remains safe is as vital as the project outcomes.

Inherent Challenges in the Workshop

A woodworking environment, while fostering innovation, also harbors various inherent risks. These range from the evident threats of sharp blades and potent power tools to the subtle perils of environmental hazards. Exposure to adhesives, paints, and minute sawdust particles can pose health challenges over time. Furthermore, there’s always the lurking danger of electrical shocks or injuries from manual tools. And, not to be overlooked, are the potential mishaps caused by loose attire or dangling jewelry interacting with moving machinery.

Balancing Rewards with Risks

The allure of woodworking isn’t just in the creation of masterpieces but also in the journey—understanding the medium, mastering the tools, and bringing visions to life. While the woodworking arena presents its set of risks, it remains a fulfilling endeavor, granted one remains vigilant. The true essence of woodworking lies in the balance between realizing its potential rewards and being perpetually conscious of its inherent risks. Knowledge of materials and tools, coupled with an adherence to fundamental safety protocols, paves the way for countless hours of gratification.

A Commitment to Workshop Safety

Casualness has no room in a woodworking workshop. Ensuring safety is a perpetual endeavor, rooted in both consciousness and compliance. Being safe isn’t about occasional diligence; it’s a continual commitment every time one steps into the workshop and engages with the tools. Central to this commitment is the ongoing acquisition of knowledge regarding safety measures. To aid in this journey, we present a compendium of woodworking safety guidelines.

Ensuring Safety in Woodworking

Given the multitude of considerations in settings where sawing and sanding are frequent activities, here are our selected top safety recommendations for woodworking:

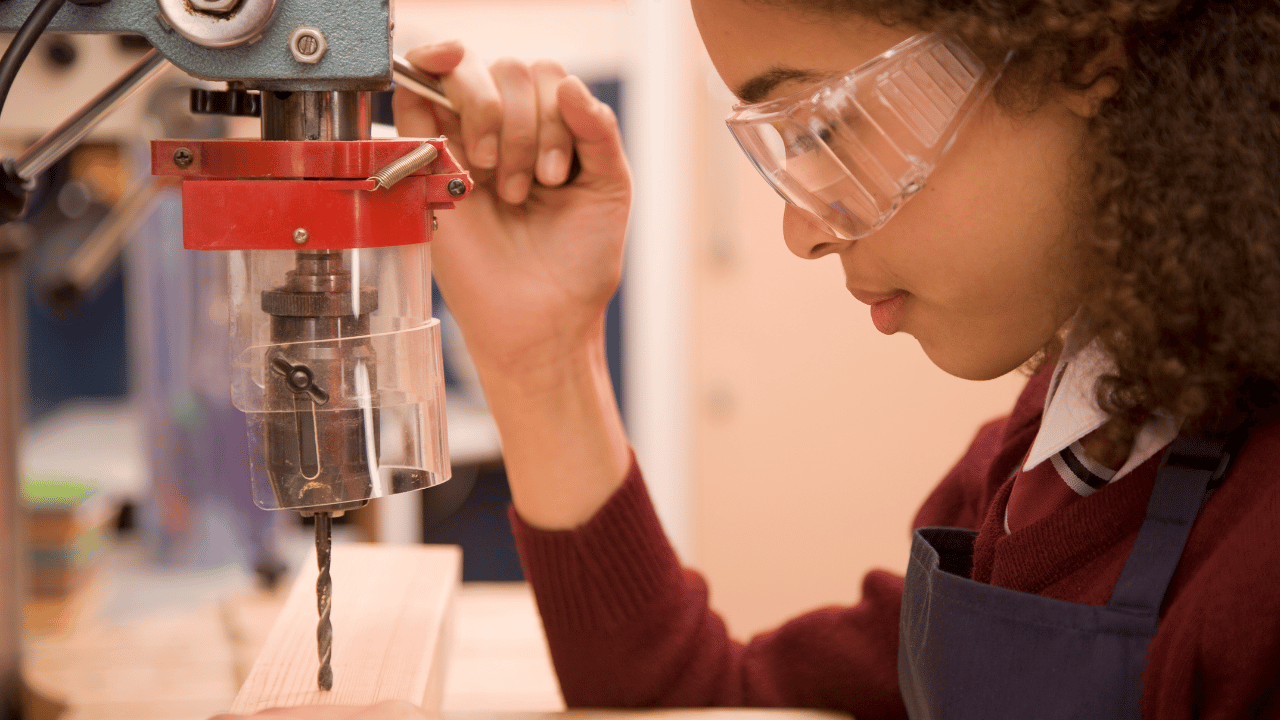

- The Importance of Protective Gear

Equipping yourself with appropriate protective gear is the cornerstone of woodworking safety. Choose clothing that fits snugly to avoid getting caught in machinery. Additionally, safety glasses will shield your eyes from wood chips and dust. Gloves offer protection from splinters and harsh chemicals such as paints and adhesives. Remember, proper respiratory and hearing protection are also indispensable, and we’ll delve more into respiratory safety later in the article.

- The Value of Mental Alertness

Maintaining a clear and sober mind is crucial when operating heavy machinery like that used in woodworking. It’s vital to avoid any substances, including alcohol and some prescription medications, that could compromise your judgment or reaction time. A clear mind is your first line of defense against accidents.

- Keeping Tools in Top Condition

Contrary to what one might think, a sharp blade is safer than a dull one. Sharp blades and drill bits make cleaner cuts, reduce debris in the air, and minimize the machine’s kick-back. Therefore, ensure your tools are in the best condition for a safe and efficient woodworking experience.

- Power Off Before Maintenance

Before you change blades or drill heads, always remember to disconnect the power. A small slip or a simple mistake can lead to severe injuries. So, it’s crucial to switch off the machine at the power source before any adjustments or maintenance.

- Inspecting the Wood

Always inspect the wood you’ll be cutting, especially if it’s reclaimed wood, which might contain hidden nails or other metal pieces. Such intrusions can damage your blades and potentially lead to severe injuries. An initial review helps you avoid sparks, blade damage, and other hazards.

- Mastering Tool Operation

Regardless of your experience level, always treat your woodworking tools with the utmost respect. Always cut square against the blade and avoid reaching over or around it. Keep all body parts away from dangerous zones, such as directly beneath a drill head. And don’t forget to use blade guards, applying them only after you’ve disconnected the power.

- Eliminating Distractions

Minimizing distractions is key to maintaining focus and ensuring safety. While some distractions are beyond your control, like someone entering your workshop unannounced, you can manage others. Keep your mobile phone on silent and refrain from playing music or radio that could divert your attention.

- Respiratory Safety

Respiratory health is a significant concern in woodworking. Regulations like the Control of Substances Hazardous to Health (COSHH) provide guidelines on Workplace Exposure Limits for hardwood and softwood dusts. One of the most effective ways to control dust levels is to employ Local Exhaust Ventilation (LEV), which involves placing an extraction nozzle right where dust and particles are generated. This measure significantly reduces the risks of respiratory conditions.

By taking these steps seriously, you not only ensure your safety but also create an environment where you can enjoy the rewards that woodworking has to offer.

- Avoid Entangling Attire and Accessories

Firstly, be mindful of what you wear. Loose clothing, work gloves, neckties, rings, bracelets, and other jewelry can easily get entangled in moving machine parts, posing a serious risk of injury.

- Beware of Awkward Operations and Hand Positions

Stay away from awkward hand positions or operational maneuvers that could result in your hand suddenly slipping into a cutting tool or blade. Keep your limbs in a natural, controlled posture to maintain a safe distance from any moving parts.

- Maintain Safe Positioning Relative to the Workpiece

Never stand directly behind the stock that is being cut, planed, or jointed. Doing so can place you in the trajectory of a potential kick-back, a common cause of woodworking injuries.

- Safe Handling of Sawdust and Cuttings

If you need to remove sawdust or cuttings from a cutting head, never use your hand while the machine is in operation. Always wait until the machine has come to a complete stop, and then use a stick or brush to clear the debris.

- Refrain from Using Compressed Air for Cleaning

Using compressed air to remove sawdust or turnings from machines or clothing is not recommended. Such actions can disperse particles at high speed, creating a potentially hazardous environment.

- Unattended Machines and Power-Off Protocols

Never leave a machine running unattended, unless it’s specifically designed to operate in that manner. Make sure to turn off the power and wait for the machine to come to a complete halt before leaving the work area.

- Handling Stalled Blades Safely

If a blade becomes stalled, do not attempt to free it without first turning off the power to the machine. Restarting a stalled blade with power still flowing can result in uncontrolled movements and subsequent injury.

- Maintaining Focus and Prohibiting Distractions

Be aware that startling or distracting someone who is operating woodworking equipment can have dangerous consequences. Similarly, horseplay has no place in a setting where machinery is in use, as it significantly increases the risk of accidents and injuries.

- The Importance of Seeking Assistance

Tackling a heavy or cumbersome workpiece single-handedly isn’t just a matter of pride—it’s a safety risk. When you attempt to manage tasks beyond your physical capabilities, the chances of incurring injuries dramatically increase. This could range from a dangerous encounter with a running blade to musculoskeletal issues like back pain. In such situations, remember that asking for help isn’t a sign of weakness; rather, it’s a proactive measure to ensure both your safety and the quality of your work.

- The Detrimental Effects of Fatigue on Work Safety

Fatigue is not just a physical state; it’s a form of impairment that can be as debilitating as being under the influence of alcohol or drugs. When you’re fatigued, your attention span narrows and your observational abilities decline. Your judgment becomes clouded and your thought processes slow down, significantly increasing the risk of accidents or errors.

If you find yourself feeling tired or mentally sluggish, pause and reassess the necessity of continuing your work at that moment. Perhaps it would be wiser to take a short nap or defer your project until you’re fully rested. Prioritizing rest is not just good for your well-being; it’s essential for maintaining a safe and productive work environment.

- Opt for a Single, Robust Extension Cord

Using multiple extension cords with power tools is not only inefficient due to current drops, but it also presents a tangle of cords that can be a safety hazard. Furthermore, these configurations often lead to disruptions when one or more connections become loose. To enhance both the efficiency and safety of your work, use a single, heavy-duty extension cord capable of delivering sufficient current over longer distances. This practice ensures your tools operate optimally, and it also contributes to a safer, more streamlined work environment.

- Avoid Reaching Over a Running Blade

The act of reaching over a running blade is fraught with peril. The risk of slipping and coming into contact with the blade is alarmingly high. Such accidents can lead to severe or even permanent injuries. Instead of taking this risk, either reach around the running blade to access areas behind it or, better still, turn off the machine and wait for the blade to stop completely. Additionally, never underestimate the importance of blade guards for enhancing your safety.

- Inspect Reclaimed Wood for Hidden Dangers

The appeal of reclaimed wood is undeniable, offering a distinctive aesthetic that many find appealing. However, old wood can harbor hidden hazards like residual nails from previous woodworking projects. Always inspect the wood carefully for nails or other fasteners before you begin working. While visual inspections can often reveal telltale signs like holes, a metal detector is invaluable if you frequently work with reclaimed wood. Either way, ensure that no nails or other foreign objects are present that could damage your saw blades or cause injuries.

- The Principle of Working Against the Cutter

One fundamental safety tip often overlooked by beginners and casual hobbyists is the importance of working against the cutter. This means directing the workpiece toward the cutting tool whenever feasible. This practice is safer than forcing the workpiece onto a work surface and minimizes the risk of dangerous kickbacks. For those who haven’t yet incorporated this principle, it might seem counterintuitive, but adopting this approach can significantly increase the safety and efficiency of your woodworking tasks.

Precautions Before Operating Woodworking Machines

Woodworking machines, while indispensable for various tasks, can pose serious safety risks if not handled correctly. Hence, before you engage with these tools, there are several precautionary steps to consider.

Ensuring Proper Training and Understanding

First and foremost, never operate woodworking machines unless you have received adequate training in their safe and proper use. Familiarize yourself not just with the basic operations but also with the safety features and emergency procedures related to the machine in question.

Studying the Owner’s Manual

Always make a point to thoroughly read the owner’s manual. This document often contains valuable information ranging from operating instructions to safety guidelines. Being well-acquainted with the manual prepares you for a safer and more effective woodworking experience.

Clarifying Doubts and Following Instructions

Before attempting any woodworking task, ensure that you fully understand the instructions and safety procedures. If any part of the operation or safety protocol is unclear, do not hesitate to ask questions or seek clarification. Lack of understanding could lead to unsafe practices, thereby putting you and others at risk.

Implementing Safety Measures for Woodworking Machines

The use of woodworking machines involves various safety precautions to mitigate risks and avoid accidents. By adhering to these guidelines, you can ensure a secure and efficient work environment.

Personal Protective Equipment: More Than Just an Accessory

It is vital to wear safety glasses, goggles, or a face shield, in conjunction with safety glasses or goggles, while operating woodworking machines. In situations where dust is generated, dust masks are advisable. If you find it difficult to hear someone speaking from a distance of three feet, this could indicate excessive noise levels, warranting the use of appropriate hearing protection.

Hand and Foot Safety Protocols

While gloves are useful for avoiding splinters when handling wood, refrain from wearing them near rotating blades or machinery parts where they can get caught. Also, consider wearing protective footwear when the job demands it.

Pre-Operational Machine Checks

Before operating any machine, confirm that the safety guard is in place, functional, and provides adequate protection. Additionally, review and adjust all other safety devices. Ensure that the machine is properly grounded and that keys and adjusting wrenches have been removed before powering it on.

Stock Inspection and Setup

Examine the stock for nails, staples, or any other potential defects prior to cutting, planing, or routing. Also, position machines so that start and stop buttons are easily accessible. These buttons should be designed to prevent accidental activation; a collar around the button can serve this purpose.

Tool Maintenance and Adjustment

It’s essential that all cutting tools and blades are sharp, clean, and in optimal working condition. Prior to any adjustments, blade changes, or inspections, ensure that the power is off and that the machine is either unplugged or its power source is locked out.

Maintaining a Safe Workspace

Utilize “push sticks” or jigs to keep your hands safe from cutting blades and always secure workpieces when drilling, sanding, or cutting. Effective lighting can significantly improve visibility, allowing for a clearer view of the workpiece, cutting blades, and machine controls. Arrange or shade the lighting to prevent glare or reflections that can distract the operator.

Flooring and Space Requirements

Maintain a clutter-free workspace that is spacious enough to accommodate the size of your workpiece without obstruction from other workers or equipment. Use extension tables or roller supports for large workpieces, and make sure power cords are either elevated or positioned to avoid becoming tripping hazards.

Ventilation and Housekeeping

Efficient and well-maintained local exhaust ventilation systems are essential for removing sawdust or chips produced during woodworking. A clean, well-lit, and well-swept work area reduces the likelihood of injuries from slips, trips, and falls.

Water and Electrical Safety

Keep your work area dry, avoiding the use of electrical equipment outdoors in wet conditions. To further safeguard against electrical hazards, keep the area free from water and moisture.

Focused Attention

Always remain focused on the task at hand. If you need to engage in a conversation or attend to something else, turn off the equipment first to ensure your complete attention and safety.

The Importance of Safety in Carpentry

Carpentry, a craft that marries art and construction, is undeniably essential in various aspects of our lives. From the homes we reside in to the furniture we use daily, the touch of a carpenter is omnipresent. However, with its significance comes the critical aspect of safety. Ensuring safety while practicing carpentry is paramount for numerous reasons:

- Prevention of Physical Injuries: Carpentry involves the use of various tools, from sharp chisels and saws to heavy machinery. A minor slip or distraction can lead to significant injuries. Being safety-conscious prevents cuts, bruises, and more severe injuries that can have long-term consequences.

- Enhanced Quality of Work: A carpenter who practices safety is more likely to produce better-quality work. When one’s focus isn’t divided between the task and potential dangers, there’s a higher concentration on precision and craftsmanship.

- Protection from Long-term Health Risks: Carpentry can expose individuals to sawdust and chemicals, which, over time, can lead to respiratory issues or allergic reactions. By adhering to safety measures like wearing masks or ensuring proper ventilation, carpenters can protect themselves from these potential health hazards.

- Cost-Efficiency: Accidents can be costly. Medical bills, damaged materials, or machinery repairs can be a significant burden. By prioritizing safety, carpenters can avoid these unnecessary expenses.

- Promotion of a Professional Image: A carpenter who emphasizes safety not only protects themselves but also sends a strong message to clients and colleagues. It showcases responsibility, professionalism, and a genuine care for the craft and those involved in it.

- Mental Peace and Confidence: Knowing that you’re working in a safe environment can be mentally reassuring. It allows for a clear mind, free from the constant worry of potential hazards, and thus, promotes confidence in one’s skills and output.

- Upholding Ethical Responsibility: Especially in larger setups or when working in teams, ensuring one’s safety is also about protecting those around. It’s an ethical responsibility to ensure that one’s actions (or lack of safety precautions) don’t jeopardize another person’s well-being.

Conclusion

Carpentry, often perceived as merely a craft of construction, transcends into an essential life skill when focused on home repairs. Mastering the basics not only empowers homeowners to tackle minor repairs and improvements themselves but also deepens their appreciation for the intricacies of the structures that surround them. From fixing a wobbly chair to patching up a worn-out floorboard, understanding the rudiments of carpentry ensures a safer, more durable, and aesthetically pleasing living environment. As we’ve journeyed through the foundational techniques and tools in this blog, it’s evident that with a bit of patience, practice, and respect for the craft, anyone can harness the power of carpentry for home repairs. So, the next time a squeaky door or a shaky table beckons, remember the basics, and take pride in the ability to meld function and form right within the comfort of your home.