Last Updated on November 27, 2023 by Pro Handyman Australia – Editorial Team

Carpentry, one of the oldest skilled professions, blends the finesse of crafting structures and objects from wood. While it involves various technicalities and skill sets, the essence of carpentry lies in the basic tools used. When discussing these tools, the debate on “sabre saw vs jigsaw” often arises, emphasizing their significance in the carpentry realm.

These tools are not just implements but extensions of the carpenter’s hands, directly influencing the outcome of their hard work. Among these, five tools stand out, being fundamental to both novice and experienced carpenters, including the often debated track saw vs table saw duo, which are essential in any woodworking arsenal.

The Hammer: Beyond Driving Nails

Firstly, the hammer signifies more than a tool; it’s a symbol of the entire craft. Predominantly used for driving nails into wood, the hammer’s utility extends to fitting parts, breaking apart objects, and even some aspects of demolition. Its versatility makes it one of the primary tools without which a carpentry project could hardly proceed. The carpenter’s skill in wielding the hammer, balancing force, and precision, often determines the quality of the assembly in the project.

Tape Measure: Ensuring Precision

Accuracy is paramount in carpentry, and that’s where the tape measure comes into play. A small, retractable tool, it’s responsible for the precise measurements necessary for cutting wood to the correct dimensions. A carpenter relies on the tape measure to avoid mistakes that could lead to material wastage or structural instability, thereby underlining its importance in every phase of the woodworking process.

Utility Knife: The Detailing Expert

When it comes to detailing, the utility knife is the carpenter’s go-to tool. With its razor-sharp blade, this tool makes precise cuts, trims edges, and helps in shaping various materials, contributing to the detailed work that adds to the project’s aesthetics. Its consistent use goes beyond carpentry, extending to other trades, highlighting its functional significance.

Chisel: Crafting Excellence

Intricacy takes physical form in carpentry through the use of the chisel. This tool, driven by hand or a mallet, excels in shaping wood, particularly in creating joints, removing unwanted wood, and making designs. The chisel helps carpenters achieve the finesse required in detailed woodworking, particularly in decorations, fitting assemblies, and crafting intricate designs.

Saw: The Essential Cutter

No carpentry workshop is complete without the saw, an essential cutting tool. The variety of saws, each designed for specific materials and cut types, speaks volumes about their necessity. From creating straight cuts with handsaws to understanding the table saw uses for larger pieces, along with the use of circular saws, a carpenter’s repertoire must include the knowledge of operating different saws. This tool’s fundamental role lies in resizing lumber to suitable dimensions, the initial, critical step in any carpentry project.

Enhance Carpentry Efficiency Using Powered Tools

Enhancing carpentry efficiency hinges on leveraging the power of advanced tools, a strategy that has revolutionised outcomes in woodworking projects. Among the game-changers in the tool repertoire is the cordless drill. This versatile device eliminates the constraints of wires and sockets, allowing carpenters the freedom to work seamlessly across various sections of their project sites. Its precision in drilling uniform holes effortlessly is unmatched, contributing to a streamlined and efficient work process.

In scenarios where height or hard-to-reach branches pose challenges, a pole saw becomes an invaluable asset. This powered saw ensures that carpenters can trim overhead branches safely and accurately, keeping their feet firmly on the ground, thereby maintaining a consistent workflow.

Equally transformative in the carpentry field is the Rotary Tool, known for its multifunctionality. With various attachments, it serves numerous purposes, from cutting and grinding to sanding and polishing, thus embodying a one-tool-multiple-functions ethos that significantly abbreviates the time and effort required for task transitions.

Lastly, the nail gun has revolutionised the way carpenters approach nailing tasks. Eliminating the need for hammers in fastening work, nail guns provide rapid, powerful, and precise nailing, drastically reducing the physical effort and time involved, especially in large-scale carpentry projects. This tool’s efficiency boosts productivity, allowing carpenters to meet tight deadlines without compromising on the quality of their craftsmanship.

These advanced tools, with their specific applications, collectively contribute to a more efficient, time-saving, and less laborious carpentry process, allowing craftsmen to achieve precision and consistency in their projects. They stand testament to how technological advancements in tooling can significantly elevate the craft of woodworking.

Carpentry Powered Tools Maintenance Tips

For carpenters, maintaining their powered tools is paramount, ensuring these instruments’ longevity and optimal performance. The first step towards maintenance is cleanliness; tools should be devoid of any lingering sawdust, debris, or residues after use. Understanding how to clean a table saw blade fits into this broader regimen, preventing residue build-up that can impair cutting efficiency. This routine might also involve using compressed air for intricate parts or a dedicated cleaning solution for the blade itself. Regular inspection for any signs of wear, especially on power cords and batteries, is vital, as these can be potential safety risks. Incorporating specific practices effectively can significantly contribute to the overall upkeep of one’s essential carpentry tools.

Proper lubrication of moving parts cannot be overlooked, as it ensures smooth operation and prevents rusting – though it’s important to use the appropriate lubricant as recommended by the tool’s manufacturer. Additionally, the sharpness of blades and bits is crucial for effective operation, meaning they should be routinely checked and replaced if necessary. Above all, adhering to a scheduled maintenance check, based on the manufacturer’s guidance, guarantees that the tools function safely and at their best capacity.

Tips for Carpentry Tools Storage

Proper storage of carpentry tools is a critical aspect often overlooked. It not only helps in maintaining the tools’ condition but also contributes significantly to a carpenter’s efficient workflow. Tools should be stored in a dry environment to avoid moisture-related damage, such as rust.

Innovative storage solutions like wall-mounted pegboards are effective for keeping tools organised and easily accessible, whereas portable toolboxes or chests with compartments are practical for carpenters who work across various locations.

Special attention should be given to the storage of power tools, ensuring cords are not twisted or damaged and batteries are removed to preserve their lifespan. Regular audits of the storage system to accommodate new tools or remove redundant ones ensure that the workspace stays functional and conducive to productive carpentry work.

Safety Measures When Using Carpentry Tools

Carpentry demands a keen focus on safety due to the inherent risks involved. Essential protective gear, including safety glasses, ear defenders, and gloves, are non-negotiables for carpenters to protect themselves from debris, noise, and potential cuts. Equally vital is maintaining an organised workspace, as neglecting cleanliness can lead to tripping or fire hazards due to sawdust accumulation and tool clutter.

Proper tool maintenance is also paramount; tools need to be sharp, clean, and functional to prevent accidents caused by extra force or unexpected slippage. Additionally, carpenters must thoroughly understand their tools’ operational details, adhering to manufacturer guidelines and using tools solely for their designed purpose. Adhering to these safety protocols ensures carpenters can operate in a risk-free environment, concentrating fully on their craftsmanship.

Power Tools vs Hand Tools in Carpentry

The power versus hand tool debate is significant in the carpentry community. Power tools, like electric saws and drills, are synonymous with efficiency and are ideal for extensive or repetitive tasks, reducing manual effort and saving time, especially in commercial undertakings. However, they necessitate electricity, come at a higher cost, and entail rigorous safety precautions.

Conversely, hand tools, including hammers and chisels, offer unparalleled precision necessary for intricate tasks, facilitating a more hands-on, quiet, and portable carpentry approach. They do, however, demand more physical exertion and consume more time. The optimal tool choice hinges on a project’s specifics and a carpenter’s proficiency, with many preferring a hybrid approach to harness both categories’ strengths.

Comparative Analysis:

| Aspect | Power Tools | Hand Tools |

|---|---|---|

| Speed | Power tools, such as electric saws and drills, dramatically increase production speed, allowing carpenters to make quick and consistent cuts or assemblies. They are the go-to for meeting tight deadlines. | Hand tools require more time and patience, given the manual effort to cut, shape, or join wood. However, this slower process allows for a meditative approach, where the journey is just as crucial as the destination. |

| Precision | With technological advances, power tools offer remarkable precision. Laser guides and automated systems ensure consistent results, especially for repetitive tasks. Yet, they may fall short in creating unique, fine details. | The precision of hand tools is born from skill rather than technology. In the hands of a master, tools like chisels and hand planes produce intricate details and finishes, celebrating human imperfection. |

| Investment | Generally, power tools demand a higher initial investment and ongoing costs in electricity or batteries. They also require proper storage conditions and maintenance to prolong their life. | Hand tools are often more affordable upfront and have fewer upkeep costs. They do need care—sharpening, for example—but it’s less reliant on external services, fostering a deeper connection between the tool and its user. |

| Portability | Some power tools are cumbersome, and their reliance on electricity limits mobility. However, cordless innovations have increased their portability, albeit with a trade-off in consistent power supply. | Hand tools excel in portability. They can be used anywhere and fit efficiently into a tool belt or box. For carpenters who travel or work on-site, this is the canvas bag of wonders they carry. |

| Learning Curve | Power tools necessitate understanding safety precautions and operational guidelines, which can be intimidating for novices. However, they make certain tasks much more approachable once mastered. | Hand tools require the development of personal technique and physical skill, often demanding more from the carpenter’s patience and dedication to the craft. Each mistake is a lesson; each success, a milestone. |

| Noise & Safety | The operational noise of power tools is significantly louder, requiring proper ear protection. While efficient, they also present higher-speed accidents, making safety training essential. | Hand tools offer a quieter, more peaceful experience, conducive to mindfulness in practice. While they pose fewer risks, the manual effort and repetitive motions can lead to physical strain over time. |

How to Choose the Right Tools for Your Project

Tool selection is critical in carpentry, influencing project efficiency, quality, and safety. Carpenters must evaluate their project’s scope and demands; detailed work might necessitate the finesse of hand tools, while substantial, rigorous tasks could benefit from power tools’ speed and strength.

Financial constraints are also guiding factors, with the necessity to allocate funds wisely, prioritising quality investment in essential tools like saws and drills. The working environment further dictates suitable tools—remote or power-scarce sites warrant cordless varieties. It’s also wise to consider tools’ compatibility with existing accessories, ensuring a well-integrated and functional toolkit.

Engaging with experienced peers, scouring reviews, and personally testing tools where possible will underpin informed choices. This meticulous approach to tool selection not only steers the project towards success but also bolsters a carpenter’s confidence and satisfaction in their work.

Reviews and User Experience on Tools Selection Use Cases

Choosing the right tools for your carpentry project involves considering the task’s specific requirements, your budget, skill level, and long-term tool utility. Below we dive into practical examples, featuring real tool brands and models, to help guide your selection process.

1. Drilling and Driving:

- Professional Use: If you’re involved in heavy-duty projects, consider investing in a high-performance drill like the DeWalt DCD997B. Known for its power, reliability, and Bluetooth connectivity, this tool can withstand rigorous use and offers customizable settings through an app.

- DIY and Home Improvements: For less intensive tasks, the Makita XFD131 is a fantastic choice. It balances power, comfort, and affordability. Its battery life is robust, perfect for extended periods of work on home projects, and it doesn’t compromise on performance.

Review Note: Users love the Makita’s 18V LXT Lithium-Ion battery for longevity and charge speed, ensuring project continuity.

2. Cutting Materials:

- Professional Use: For diverse cutting needs, the Milwaukee 2730-20 M18 Fuel circular saw is a powerhouse. It cuts through even the toughest materials with ease, offering long battery life and ergonomic design to reduce fatigue during long projects.

- Occasional Use/DIY: The BLACK+DECKER 7-1/4-Inch Circular Saw (BDECS300C) is an ideal tool for DIY enthusiasts. It handles most woods used for home projects and includes a laser guide for precision, ensuring straight cuts.

Review Note: The Milwaukee’s POWERSTATE Brushless Motor appeals to professionals needing maximum power and efficiency, often outperforming corded counterparts.

3. Detailed Woodwork:

- Professional Use: When precision is paramount, as with joinery or detailed finishing, the Festool 574332 Domino DF 500 Joining System shines. Though a significant investment, its revolutionary cutting method, and adjustable settings justify the cost for serious woodworkers.

- Hobbyists and DIY: The Dremel 4300-5/40 rotary tool kit is versatile for those who enjoy detailed work but don’t require industrial-grade equipment. It’s compatible with numerous accessories, catering to intricate carving, engraving, or finishing.

Review Note: The Dremel’s universal 3-jaw chuck is a highlight for users, allowing easy accessory changes and adapting to various tasks without needing a tool change.

4. Smoothing Surfaces:

- Professional Use: The Makita 9403 Belt Sander with its quiet operation, 4″ wide belt, and speed makes quick work of large surfaces. It is built for heavy-duty use, perfect for professional settings.

- Occasional Use/DIY: For less frequent use, the DEWALT Palm Sander (DWE6411K) is an excellent choice. It’s less aggressive than a belt sander, perfect for smaller projects, and offers a comfortable, ergonomic grip.

Review Note: DEWALT’s built-in counterbalance system reducing vibration has been a favorite feature, significantly minimizing user fatigue.

5. General Hand Tool Kit:

- Everyone: A comprehensive hand tool kit is beneficial for everyone, from the professional carpenter to the home DIYer. The Stanley 94-248 65-Piece Homeowner’s DIY Tool Kit covers all the essentials. It includes a hammer, tape measure, screwdrivers, pliers, and more, all housed in a portable, rugged case.

Review Note: Users appreciate the Stanley kit’s quality and range, providing a solid foundation for various projects without unnecessary specialty tools.

FAQ: Essential Carpentry Tools

1. What tools are fundamental in carpentry?

The hammer, saw, tape measure, chisel, and utility knife are crucial in carpentry, providing the basis for most woodworking tasks.

2. Why is the hammer essential?

Hammers are vital for tasks like driving nails into wood and making fine adjustments to fit wood pieces together.

3. How important is a tape measure?

Tape measures are key to ensuring accurate cuts and alignments, which are critical for the structural integrity of carpentry projects.

4. What role does a utility knife play?

Utility knives are used for precise cuts, trimming, and fine-tuning wood pieces, essential for detailed work.

5. Why do carpenters use chisels?

Chisels help in carving and shaping wood, especially in creating joints or intricate designs, requiring precision.

6. Do carpenters need different types of saws?

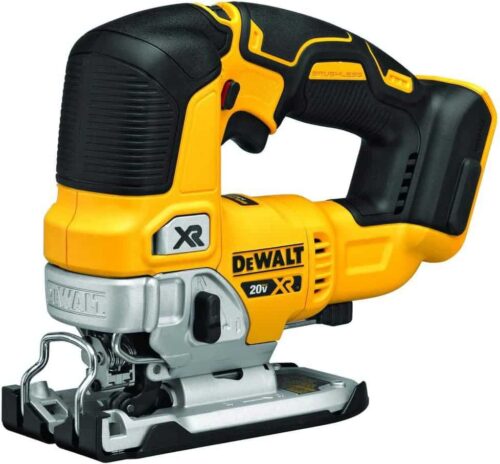

Yes, various saws are used for different cuts; for example, handsaws are ideal for straight cuts, while jigsaws handle curved patterns.

7. Can beginners start with these tools?

Absolutely, these essential tools offer a great starting point for beginners to learn basic carpentry skills before moving on to more complex tools and tasks.

Conclusion

These five tools form the backbone of carpentry. Their roles are intertwined across the various stages of carpentry work, laying the foundation right through to adding the finishing touches. Mastery of these tools, understanding their capabilities and limitations, is essential for anyone seeking excellence in the carpentry field.

Beyond the carpentry skill and experience, the true artistry of carpentry lies in how well a craftsman uses these tools to bring creations to life. The harmony between the carpenter and their tools elevates this craft, turning simple pieces of wood into extraordinary works of art and utility.