Last Updated on October 16, 2023 by Pro Handyman Australia – Editorial Team

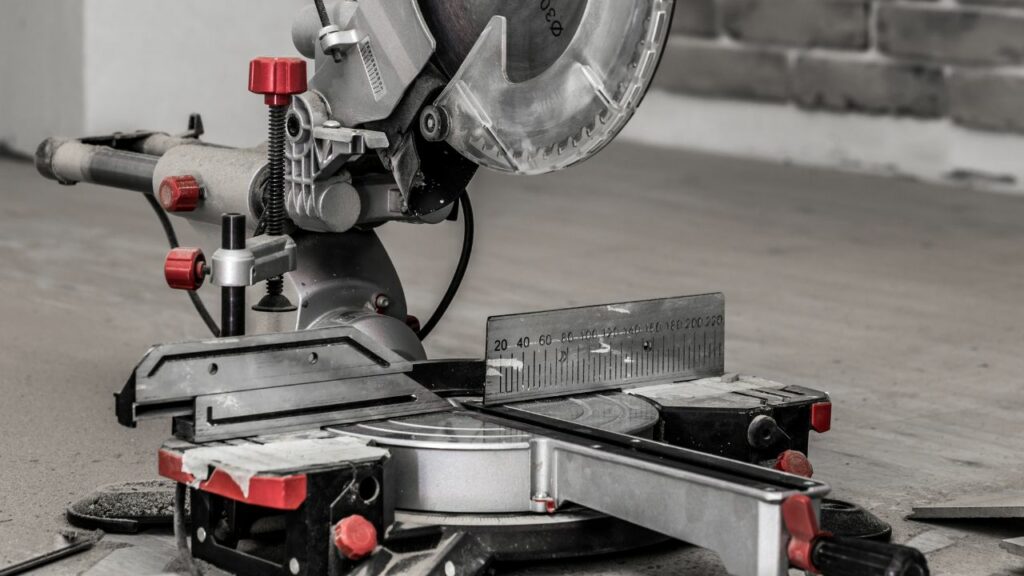

Can You Cut Metal with a Miter Saw? A Comprehensive Insight

Miter saws, traditionally champions in woodworking, have often left craftsmen and hobbyists pondering a pivotal question: can these versatile tools also cut metal? The simple answer is, “Yes, they can.” But while their motor can accommodate the task, the default blade designed for wood might not be apt for metals. To safely and effectively delve into metal cutting with a miter saw, it’s vital to consider several factors.

Understanding the Miter Saw’s Metal Cutting Capabilities

While miter saws are known for their prowess in woodworking, many users often wonder if they can handle cutting metal as well. However, like any task, using the right tools and accessories becomes crucial. Transitioning from wood to metal cutting isn’t merely about the capability but also about ensuring efficiency, safety, and precision. It’s not just about if it can be done, but how well it can be done. Generally, a miter saw’s motor can handle the density and toughness of metallic materials. However, the default saw blade designed primarily for wood might not be the most suitable for metal cutting.

Selecting the Right Blade for Metal Cutting

The heart of the challenge often lies in the saw blade. A miter saw blade designed for wood, when used on metal, can lead to several issues:

Operational Speed Discrepancies: Miter saws are calibrated for the softer grains of wood, meaning their operational speeds might be too fast when introduced to metals. This mismatch can result in excessive friction.

Impacts of Excessive Friction: Apart from leading to compromised cut quality, the heat generated by the friction can also cause structural changes in the metal, like warping

Tool Strain and Overheating Risks: The saw itself isn’t immune. Continual exposure to high friction levels can strain the miter saw’s motor, reducing its lifespan and elevating malfunction risks.

Safety First: The rapid blade rotation not apt for metal, coupled with the generated heat and sparks, makes for a hazardous working environment. There’s an amplified risk of injuries, potential fires, and workspace damages.

In essence, while the miter saw holds the potential for metal cutting, equipping it with the correct blade becomes paramount. Proper preparation guarantees not just quality but also safety and equipment durability.

The Perils of Inappropriate Blade Use in Metal Cutting

Venturing into metal cutting demands more than just enthusiasm; it requires meticulous attention to detail, especially concerning saw blade choice. Using an ill-suited blade can cascade into a series of challenges:

Speed and Friction Issues: A blade ideal for wood can interact negatively with metals due to mismatched speeds, leading to unnecessary friction

Heat-Related Complications: This unwanted friction causes both the metal and tool to overheat, compromising the metal’s structure and the cut’s quality.

Safety and Equipment Longevity Concerns: Overheated tools and metals not only pose a direct threat to the user but can also shorten the tool’s life expectancy. The combined threats of sparks, flying metal shards, and a fast-spinning blade can be perilous.

The takeaway? The blade’s importance in metal cutting can’t be stressed enough. Right compatibility ensures not only work quality but also user safety and tool longevity.

Understanding the Basics: Chop Saw vs. Cut Off Saw vs. Mitre Saw

Chop saws and cut off saws are designed to make straight cuts across profiles at a 90° angle, while mitre saws are specifically designed to cut across profiles at various angles. However, a mitre saw, when equipped with the right metal cutting blade, can efficiently cut through steel and aluminum profiles at an angle. All these saws come equipped with a ‘cutting plinth’, a static cutting area integral to their design.

Though traditionally used for woodworking, a mitre saw, when equipped with the right blade, can efficiently cut through steel and aluminium profiles at an angle. There are specialized blades available for cutting through aluminium and non-ferrous metals, while high-performance discs are tailored for steel and stainless steel to ensure precise, clean cuts. A comprehensive range of power tool accessories suitable for these tasks is widely available.

Choosing and Maintaining Miter Saw Blades for Metal Cutting

The blade that comes with your mitre saw, while excellent for wood, is not designed to cut metals. Using it for such can lead to accidents and damage. Although some mitre saws can cut non-ferrous metals like aluminum or copper, it’s not a long-term solution for metal cutting.

For those moments when you need quick, precise cuts into metal and lack a more specialized tool, changing your wood-focused blade to a metal-appropriate one is the way forward. Fortunately, there is an array of high-quality metal-cutting blades available. When selecting a blade, consider your specific needs, like opting for triple-chip grind blades for finer cuts or composite blades for varying material densities.

The market is flooded with an assortment of saw blades, each catering to specific tasks. Here’s a comprehensive breakdown:

Aluminum Oxide Blades: These blades are custom-crafted for metals, specifically aluminum bars and pipes. Their precision and efficiency in such tasks are unparalleled.

Diamond Blades: These are versatile and can tackle tougher materials like cast iron. However, they grind through materials, which may lead to faster wear and tear.

Carbide Blades: Their resistance to wear makes them perfect for metals, including steel roofing and other robust materials. Optimal performance can be achieved by regulating the blade speed.

For aluminum, which is delicate yet sturdy, a blade with a TPI between 14-16 ensures the metal remains undamaged during cuts.

Adapting a miter saw for metal cutting can, over time, affect the longevity of the blades due to the heightened speed and pressure requirements. While a miter saw in its pristine condition, subjected only to its primary function, can last for years, introducing it to metal cutting might reduce its lifespan.

Hands-On Experience with Cutting Metal Using Miter Saws

One can easily get lost in the plethora of technical specifications and marketing jargon that surround power tools, but it’s often the real-world, hands-on experiences of craftsmen that provide the most valuable insights.

Timothy, a seasoned craftsman, recently shared his experience using the Bosch GCM 350-254 Sliding Mitre Saw “I’ve had my share of challenges with cutting metal, especially aluminum, but the GCM 350-254 has truly been a game-changer,” he revealed. He further commented on the saw’s impressive durability, highlighting a particular project where he had to cut through some non-ferrous metals. “The precision was on point, and I felt in control throughout,” Timothy added.

In contrast, Sarah, an enthusiastic DIYer, vouched for the DeWalt FLEXVOLT® 12 in (305 mm.). “I took on a backyard project, and the FLEXVOLT® 12 was my companion,” she shared. With its ergonomic design and the power to match, Sarah’s user experience underscored the fact that choosing the right miter saw can make all the difference.

These personal accounts, and countless others, emphasize the importance of hands-on experience and how it can greatly influence one’s perspective on a tool.

In-depth Comparisons of Miter Saws for Metal Cutting

The world of miter saws is competitive, with numerous brands vying for the top spot. To help our readers navigate this, we’ve curated an in-depth comparison of the top-performing miter saws in the market.

| Model | Power | Longevity | Price |

|---|---|---|---|

| Bosch GCM 350-254 Sliding Mitre Saw | 15 Amps | 5+ years | $450 |

| DeWalt FLEXVOLT® 12 in (305 mm.) | 14 Amps | 4.5 years | $400 |

| Makita LS1040 10″ Compound Miter Saw | 15 Amps | 5 years | $460 |

| Ryobi #TSS121 | 13 Amps | 4 years | $350 |

While the Bosch offers impressive power, the Ryobi model provides a more budget-friendly option without compromising much on the longevity. The DeWalt, with its unique features and reliable performance, holds its own against the slightly more powerful Makita. This table only scratches the surface, and for those looking for more granular details, be sure to check out our article titled “The Best Product Reviews” for a comprehensive analysis.

Best Practices for Precision Metal Cutting with Saws

For a smooth, efficient, and safe cutting metal experience, follow these guidelines:

- Safety First: Always wear eye protection, gloves, and ear defenders during metal cutting operations to shield yourself from flying metal shards and chips.

- Protecting the Motor: If your mitre saw has an open motor housing, shield the motor from metal debris by covering the openings and vents with a thin cloth.

- Cutting Hollow Profiles: When working with hollow or thin-walled profiles, such as aluminium angles, support the metal with a wooden backing. This minimizes the risk of the blade snagging on the metal and causing deformations.

- Preparation: Before powering on the saw, inspect the guard to ensure it’s in good condition and correctly positioned. Clear all cables from the cutting zone for safety.

- Secure the Workpiece: Lay the metal on the saw table and use vice adjusters or mitre locks to hold it firmly against the fence. This ensures a precise cut.

- Initiating the Cut: Once you’re content with the machine setup, press the saw’s power switch and wait for the blade to reach its maximum speed. Then, steadily lower the blade through the metal. After completing the cut, keep the saw in its lowered position and switch off the power. Retain a firm hold on the workpiece until the blade halts completely. Once it does, revert the blade carriage to its original position.

Miter saws are renowned for their precision and versatility in cutting wood. Whether it’s accurate degree crosscuts, bevel cuts, or compound cuts, this power tool is a favorite among woodworkers and DIY enthusiasts. Its strength lies in delivering exact cuts, which is invaluable for intricate woodworking tasks.

Mitre Saw for Metal Cutting: Delving into Practicality and Risks

The mitre saw, renowned for its precision in woodworking, has often been a topic of debate among craftsmen when it comes to metal cutting. While the tool does possess the ability to slice through metals, its suitability for consistent metalwork remains questionable. Here are some key factors that shed light on this discussion:

- Economic Implications of Blade Replacements:

Using a mitre saw for metal cutting might seem like a straightforward adaptation, but the hidden costs can quickly add up. Blades designed for woodworking wear out more swiftly when used on metals. Continual replacements not only weigh on the pocket but also disrupt work continuity. Over time, the cumulative cost of frequent blade replacements can rival or even exceed the cost of investing in a tool specifically designed for metal cutting.

- RPM Discrepancies and Ensuing Safety Hazards:

The mitre saw operates at a high rotations per minute (RPM) rate, optimized for woodworking. However, metal cutting generally demands a slower blade speed for precise and safe cuts. When a mitre saw, with its higher RPM, is used for metalwork, the result can be a shower of excessive sparks. This not only poses a risk of fire but also becomes a safety hazard for the operator, especially without proper protective gear.

- Motor Longevity and Overheating Concerns:

Metals, given their density, naturally generate more resistance and friction during cutting. This means that the mitre saw’s motor has to work harder, leading to overheating issues. Prolonged exposure to such conditions can strain the motor, ultimately impacting its efficiency and potentially shortening its operational lifespan.

- Assessing the Frequency of Metal Cutting Tasks:

For craftsmen whose projects involve occasional metal cuts, a mitre saw, with all precautions, might be an acceptable solution. However, if metalwork is a staple in your craftsmanship repertoire, specialized tools like chop saws or circular saws are worth the investment. These tools are designed with the specific challenges of metal cutting in mind, ensuring not only efficiency and precision but also longevity and safety.

Understanding Metal Varieties for Cutting

Metals come in diverse forms and types, each with its own unique properties and characteristics. When considering cutting metals with a saw, it’s imperative to understand these variations to achieve the desired result.

The Role of Metal Thickness

While thickness is an important factor in determining the ease of cutting, it’s essential to note that the sawing process is more gradual than a straightforward chopping action, akin to using a machete. Thus, the kind of metal with a miter often has a more pronounced impact on the cutting metal experience than its thickness.

Hard vs. Soft Metals: Know Your Material

The type of metal plays a significant role in the cutting process. For instance, if you’re working with a soft metal like tin, the process is relatively straightforward. However, harder metals such as steel, tungsten, or cobalt present more of a challenge. Cutting through these metals will demand more time and a specialized blade tailored for such materials, perhaps a carbide tipped blade, which is known for its durability.

Navigating the Challenges of Aluminum

Aluminum is a commonly used construction material, but it can pose challenges when cutting, especially if you’re dealing with thicker forms. Classified as a “non-ferrous” metal, aluminum requires a specific type of blade designed for non-ferrous metals to ensure a clean and efficient cut.

A Look at Other Non-Ferrous Metals

In addition to aluminum, several other metals fall under the non-ferrous category, including:

- Brass

- Copper

- Lead

- Tin

When cutting non-ferrous metals, it’s crucial to use the right tools and blades to achieve the best tool results and maintain safety standards.

Understanding the Limits of the Miter Saw’s Motor Power

Central to the miter saw operations is its meticulously designed motor, tailored to cater to the nuanced demands of woodworking. This configuration ensures that intricate tasks, such as trimming or crafting detailed wood cuts, are executed seamlessly. But metals, especially robust variants like aluminum, present a stiffer resistance. Engaging a miter saw’s motor to navigate through metals can exert considerable strain on it. While the device can technically handle both ferrous (iron-containing) and non-ferrous metals, this venture is not without its perils. Two immediate concerns that surface are potential damage to the saw blade and the generation of sparks during cutting metal, both of which warrant careful attention.

Blade Selection: Prioritizing TPI and Material for Metal Cutting

When we talk about woodworking, the standard blade tooth count oscillates between 60 to 80, allowing craftsmen to achieve the required precision. Blades with carbide tipped teeth can facilitate smoother cuts on different materials. But, metal isn’t as forgiving as wood. The toughness and rigidity of metals demand blades with finer teeth, facilitating smoother cuts.

Health Check: Assessing the Condition of Your Miter Saw

Before one ventures into the challenging world of metal cutting, a health check of the miter saw becomes a mandate. Remember, its primary design revolves around wood. Evaluating its current condition, performance capabilities, and any signs of wear and tear will offer insights into its readiness for tougher tasks like metal cutting.

Managing Expectations: The Miter Saw’s Metal Cutting Efficiency

It’s essential to understand that while miter saws are champions in woodworking, their prowess in metal cutting might not be equally commendable. Recognizing this differential helps in setting realistic expectations when you cut metal.

Prioritizing Safety in Metal Cutting with a Miter Saw

Regardless of one’s craftsmanship level, if you’re venturing into metal cutting with a mitre saw for the first time, it’s crucial to adhere to some vital safety guidelines:

- Always clear away dust and debris before placing any metal under the blade. The combination of increased heat, friction, and an unclean surface can result in jagged cuts.

- Thoroughly clean the workstation of wood residues before metal cutting, as the hot metal chips and sparks generated can be a fire hazard.

- Ensure you only begin cutting once the mitre saw has reached its full speed, and maintain a slow and steady pace.

- Lastly, never underestimate the importance of personal protective equipment. Always ensure you’re wearing appropriate safety gear during the cutting process.

Arming the saw with the right blade, acclimating with the appropriate cutting metal speeds, and in-depth knowledge about the saw’s motor mechanics will undoubtedly pave the way for a successful metal cutting experience. Always refer to the user manual to acquaint yourself with safety precautions. It’s also vital to let the blade reach its full momentum before initiating the cut, ensuring a clean finish and minimizing metal damage. And remember, safety gear isn’t optional; it’s essential.

Beyond Miter Saws: Exploring Other Metal Cutting Avenues

FFor those keen on cutting metal, there’s a world beyond miter saws. Other saws, like chop saws, are more specialized. Tools like chop saws, circular saws equipped with abrasive discs, and compound sliding miters (often mistaken for chop saws) offer more specialized solutions. For instance, the Bosch CS10 Circular Saw, when armed with a ferrous metal cutting blade, becomes a powerhouse for cutting steel and angle iron. Rotary tools emerge as frontrunners for stainless materials. Renowned brands, including Evolution Power Tools and DeWalt, have also ventured into the realm of metal cutting blades. But a visit to the local hardware store can offer more personalized options.

The Final Verdict: Weighing the Pros and Cons of Using a Mitre Saw for Metal Cutting

, when armed with a ferrous metal cutting blade, becomes a powerhouse for cutting steel. While the occasional metal cutting task is achievable with the right blade and safety measures, one must always be aware of the inherent limitations and potential hazards.

Conclusion

Selecting the right tools for any task is the cornerstone of achieving precision, efficiency, and most importantly, ensuring safety. Each tool has been meticulously designed, keeping in mind its primary purpose and the challenges it will face during its operation. The mitre saw, for instance, is an exemplary tool tailored for woodworking. Its structure, blade design, and motor are all optimized for cutting through wood with unmatched accuracy and ease.

While modern innovations and adaptability have allowed craftsmen to use the mitre saw for metal cutting, it’s essential to exercise caution. Adapting a tool for purposes other than its primary design introduces a new set of challenges. For instance, metal’s density and hardness demand different blade types and motor capacities. While occasional metal cutting with a mitre saw is feasible under specific conditions, using it as a regular metalwork tool could compromise both the equipment’s integrity and the safety of the operator.

As craftsmen, DIY projects enthusiasts, or even professionals, our goal is always to produce the best quality work. To achieve this, tools that are explicitly designed for the job should always be at the forefront of our choices. There’s a vast array of specialized tools available in the market, each catering to specific materials and tasks. Leveraging these tools ensures not only the longevity of your equipment but also the quality and safety of your work.

In the dynamic world of craftsmanship, new challenges and questions will inevitably arise. Whether it’s about tool selection, techniques, or materials, remember that there’s a wealth of knowledge out there. Expert advice, whether from seasoned craftsmen, construction industry professionals, workshops, or even online platforms, can provide invaluable insights. As you venture into future projects, bear in mind the importance of matching the right tool with the job. And always remember, while creativity knows no bounds, safety should never be compromised. Here’s to achieving excellence in all your endeavors and ensuring safe crafting!