Last Updated on December 1, 2023 by Pro Handyman Australia – Editorial Team

When it comes to choosing between a jigsaw and a circular saw, the best option depends on the nature of your project. When comparing different types of saws for woodworking projects, it’s essential to understand each tool’s unique capabilities. If you require intricate, curved cuts and the ability to maneuver in tight spaces, the jigsaw is your go-to tool. However, for fast, straight cuts, especially in larger materials, the circular saw stands out. In this context, it might also be helpful to consider the advantages of other saws in the market, leading to a comparison of table saw vs miter saw and also table saw vs mitre saw vs circular saw, each of which excels in specific tasks. Below, we explore the fundamental differences between these two power tools, along with the jigsaw and circular saw, helping you quickly identify which saw is most suitable for your specific needs.

Quick Overview: Identifying Your Needs

On the other hand, circular saws, with their robust and high-speed spinning blades, are tailored for straight cuts. They easily slice through thick materials like large wooden planks or plywood, offering speed and efficiency, which is quite different from the table saw uses that are more varied and often include precise and intricate cuts. For construction projects or when you have to cut large volumes of material, a circular saw is indispensable.

Understanding the Unique Attributes of Jigsaws and Circular Saws

Jigsaw Strengths and Uses: The unique design of a jigsaw, with its narrow, vertically-oriented blade, makes it unparalleled for detailed work. Its ability to create complex cuts – from curves to angles – is why many prefer it for tasks like fitting countertops, creating custom furniture elements, or crafting artistic designs. It offers a level of control that is difficult to achieve with bulkier saws.

Circular Saw Strengths and Uses: Conversely, the circular saw, characterized by its circular blade, is a powerhouse for making long, straight cuts and is replete with interesting circular saw facts. It’s designed for efficiency and can quickly rip through boards or make crosscuts. Whether you’re framing a house or building a deck, the circular saw is known for its precision in straight cutting, making it a favorite in worksites.

By understanding these core attributes and evaluating your project’s needs, you can easily decide between a jigsaw and a circular saw. Each tool offers specialized functionalities, and choosing the right one can significantly enhance your work quality and efficiency.

Exploring the Dynamics of a Jigsaw

A jigsaw is a handheld power tool defined by its thin, vertically oscillating blade. Available in both corded and battery-powered versions, this tool offers flexibility and convenience in various cutting scenarios.

Delving into Jigsaw Blades and Base Plate

Jigsaw blades come primarily in two forms: U-shank and T-shank, denoting the manner in which they lock into the saw. Among these, T-shank blades garner preference for their ease of installation — a simple button flip securely affixes them, preventing accidental detachment.

Conversely, U-shank blades necessitate a more tedious setup, involving a specific wrench to fasten a nut securely, ensuring the blade’s stability. Given the propensity for jigsaw blades to dull or break, the simpler, more efficient blade-changing process of T-shank blades is more advantageous.

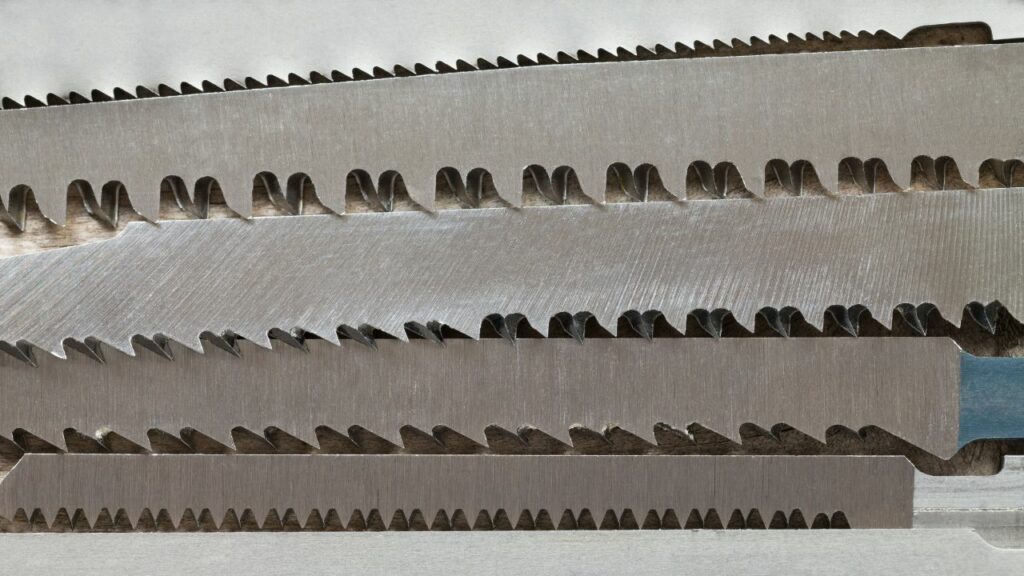

The functionality of jigsaw blades extends to various tooth configurations and orientations. The term “TPI” or teeth-per-inch indicates the coarseness of the cut, influencing both speed and finish quality. Lower TPI blades work faster, though at the expense of a rougher finish, while higher TPI options offer slower, yet finer cuts.

Specific blade designs also cater to unique materials, such as Plexiglass or soft metals like aluminum, ensuring integrity and quality of the cut. Furthermore, the direction of the blade teeth impacts the cutting dynamics. Upward-pointing teeth engage the material during the blade’s up-stroke, stabilizing the saw but potentially compromising the material’s upper surface finish.

In contrast, downward-pointing teeth minimize upper surface blemishes, although controlling the saw may require more effort as it tends to push away from the material. This nuanced understanding of blade characteristics allows users to select the ideal jigsaw blade for pristine, precise results.

The foundational support of a jigsaw, known as the base plate, bears resemblance to that of a circular saw, providing stability and guidance during cuts. Notably, it features markings that assist in maintaining the accuracy of straight cuts. Furthermore, its adjustable nature accommodates bevel cuts by tilting to various angles as per the user’s requirements. However, it’s vital to acknowledge the limitation imposed by the inability to modify the cutting depth with a jigsaw, a restriction determined by the length of the blade. In contrast, the circular saw offers the flexibility of depth adjustment, enhancing its versatility in handling different materials and cut depths.

Optimal Scenarios for Utilizing a Jigsaw

Boasting a plethora of applications, the jigsaw is an invaluable tool for executing straight, beveled, and, with sufficient expertise, plunge cuts. Its standout capability lies in crafting curved designs such as circles or arches, courtesy of its proficiency in executing tight curves and intricate angles, akin to the functionalities of bandsaws and scroll saws. Projects demanding the crafting of circular patterns or intricate curvatures, like a DIY wooden Christmas tree, are ideally suited for the unique capabilities of a jigsaw.

Mastering the Jigsaw: Usage Guidelines

While comprehensive tutorials on operating a jigsaw are available, several fundamental steps can enhance your initial experience. It begins with meticulous measurement and marking of the intended cut. For elongated straight cuts, which may present control challenges, employing a jigsaw guide proves beneficial. Prior to cutting, it’s crucial to ensure the blade reaches maximum speed, post-trigger activation, for a smooth initiation.

Moreover, discerning the ‘good side’ of your workpiece is essential, especially if blade motion dictates that the cleaner side of the cut will be underneath. Pre-cutting excess material is a recommended strategy, simplifying the execution of tight turns. Relief cuts leading up to the marked line facilitate better blade movement, offering superior control over the tool during intricate tasks.

Addressing Common Queries Surrounding Jigsaw Usage

- Achieving Straight Cuts with a Jigsaw:

The pursuit of perfectly straight cuts using a jigsaw often poses a challenge, possibly requiring more hands-on practice or the assistance of a jigsaw guide. This attachment helps maintain the saw’s course, ensuring straighter lines.

- The Feasibility of Cutting 2x4s:

While jigsaws can technically cut through 2×4 lumber, the blade must extend at least one inch below the material at its lowest point. However, precision and cleanliness of the cut may be compromised due to the blade’s tendency to flex within such thick material, resulting in less stable cuts.

- Addressing Angular Divergences in Cuts:

If your jigsaw veers off into an angled cut, it may indicate a bent blade or an incorrectly adjusted base plate. It is crucial to verify that your blade aligns at a 0-degree angle and that the base plate remains flush against the material during the cut, minimizing any lateral movement that could alter the cutting trajectory.

Understanding the Circular Saw: Functionality and Blade Dynamics

A circular saw operates on a mechanism akin to a table saw, utilizing a rotating blade to execute cuts. Unlike a table saw, where the material is maneuvered through a stationary blade, the circular saw introduces the blade to the material, enhancing control and precision. The quintessential circular saw blade resembles a disc, predominantly measuring 7.25 inches, although more compact versions, measuring approximately 5.5 inches, are available for nuanced tasks. This blade is safeguarded by a retracting guard for enhanced safety during operation.

The efficacy of a circular saw blade is partially determined by its tooth count. Blades boasting a higher number of teeth deliver cleaner, more refined cuts, making them optimal for hardwood materials. Conversely, blades with fewer teeth expedite the cutting process. However, it’s paramount to recognize that the blade’s sharpness and overall quality have a pronounced impact on the cut, overshadowing the influence of tooth count. Regular replacement or sharpening of blades sustains their efficiency, ensuring consistently high-caliber performance.

Insights into Circular Saw Components

The base plate of a circular saw mirrors the functionality offered by its counterpart on a jigsaw, providing a stable platform that facilitates the saw’s smooth movement across the material. For precision in straight cuts, the saw can glide along the edge of a specialized circular saw jig, a component that can either be crafted personally or acquired commercially.

This base plate is not bereft of reference markers, designed to assist in maintaining alignment for accurate cuts. Additionally, it grants the user the ability to perform angle adjustments for bevel cuts. A distinctive feature of the circular saw’s base plate is its adjustable depth, a significant divergence from jigsaws. This adjustability is instrumental when fashioning grooves or partial cuts within a board, without penetrating it entirely.

When and How to Employ a Circular Saw

The circular saw excels in producing straight cuts and is particularly adept at handling extensive, straight incisions in unwieldy materials like plywood, which are typically inconvenient for a table saw. It has the versatility to substitute for a table saw or a miter saw, despite the setup for cuts requiring more meticulous preparation and time investment.

For individuals with limited space but requiring a robust cutting tool, the circular saw emerges as the recommended choice. Those encountering difficulties in achieving straight, immaculate cuts could consider transitioning to a track saw for improved accuracy and convenience.

Operating a circular saw requires adherence to certain guidelines to ensure precision in your work and safety in your workshop. Begin by acquainting yourself thoroughly with your specific saw model. This involves a careful review of the manual, ensuring you understand the operational nuances before initiating any cuts.

Preparation of your material is equally crucial. The material must be supported in a manner that prevents the blade from pinching during the cutting process. Utilizing a thick slab of foam insulation as a supportive base is a recommended approach. Precision is key when measuring and marking your intended cut. It’s important to factor in the width of the blade and consistently focus on cutting along the waste side of the marked line. Employing a circular saw guide enhances your ability to execute an impeccably straight cut. When initiating the cut, allow the saw to reach its maximum speed before engaging the material. Employ a consistent, steady motion, and remain vigilant of hand placement throughout. Towards the conclusion of the cut, you may find it necessary to visually track the blade, ensuring adherence to the cutting line.

Addressing Common Queries About Circular Saws

When deliberating between a jigsaw and a circular saw, the context of use becomes paramount. Jigsaws offer versatility for various tasks but may fall short in delivering clean, straight cuts due to the inherent flexibility of their blades. Circular saws promise superior precision but can be somewhat daunting for novices.

The optimal solution may be an investment in both tools. Consider starting with cost-effective, cordless models from a consistent brand, allowing for interchangeable battery use. This duo forms the cornerstone of essential tools for aspiring woodworkers, promoting operational safety and skill development.

It’s undeniable that circular saws, while efficient, pose a significant safety risk. However, adherence to stringent safety protocols substantially mitigates the likelihood of accidents. Ensuring conscious awareness of finger placement and adopting a no-risk policy is fundamental.

Regarding the utility of cordless circular saws, they are indeed a valuable investment. Their portability facilitates use in various locations beyond your primary workshop, eliminating the inconvenience and potential hazard of maneuvering extension cords. This convenience, coupled with the eliminated risk of severing the cord, underscores their worth.

Prioritizing Your Purchase: Which Saw Comes First?

For those prioritizing straight cuts or engaging in numerous DIY projects, the circular saw emerges as the preferred initial purchase, often complementing the miter saw uses in more specialized tasks. It promises cleaner and more accurate cuts, enhancing the quality of straight-line cutting tasks, while the miter saw excels in precise angular cuts.

Conversely, for beginners or those apprehensive about handling power tools, the jigsaw serves as a more user-friendly option. Its operation presents a gentler learning curve and poses fewer risks, ensuring a safer experience for novices.

Hands-On Experience with Jigsaw and Circular Saw

Navigating the world of cutting tools can be overwhelming, especially when trying to decide between a jigsaw and a circular saw. To provide a clearer picture, we delved into user experiences with popular models from renowned brands, showcasing real-life applications and performance.

One particular story stood out from a freelance carpenter, Alex, who recently embarked on a kitchen remodeling project. Alex used the BLACK+DECKER 400W Jigsaw, a jigsaw known for its precision and control. According to him, the device was a game-changer when it came to cutting countertops and crafting cabinetry with intricate designs. The saw’s variable speed settings allowed for impeccable accuracy, essential for the detailed work he was undertaking.

On the other side, we heard from Jamie, a DIY enthusiast who specializes in creating custom shelving units. She opted for the Ryobi P505, praising its power and the clean, straight lines it produced. Jamie found it especially useful for quickly cutting large plywood sheets, a task that would have been more challenging and time-consuming with a jigsaw. The Ryobi P505‘s easy-to-adjust depth setting also facilitated repeated cuts of the same depth, making her shelving projects a breeze.

These firsthand accounts highlight the importance of choosing the right tool based on the specifics of your project, confirming that both jigsaws and circular saws hold significant places in woodworking and renovation realms.

In-Depth Comparisons: Jigsaw vs Circular Saw

When selecting the ideal tool for your needs, understanding the nitty-gritty differences is crucial. Below is a comparison table reflecting the performance of top-tier models from reputable brands, offering insights beyond basic functionalities.

| Feature | BLACK+DECKER 400W (Jigsaw) | Ryobi P505 (Circular Saw) |

|---|---|---|

| Power | 6 Amps | 15 Amps |

| Speed (SPM/RPM) | 3,000 SPM | 5,500 RPM |

| Cordless Option | Yes | Yes |

| Weight | 5.2 lbs | 8.8 lbs |

| Price | $129 | $159 |

| Cut Precision | High (curves and angles) | Moderate (straight lines) |

| User-Friendliness | Moderate | High |

The BLACK+DECKER 400W Jigsaw shines in tasks requiring high precision in curved and angled cuts, making it ideal for detailed work. However, the Ryobi P505 outperforms in speed, power, and straight cuts, suited for heavy-duty tasks and handling thicker materials.

Conclusion

In conclusion, while the utility of circular saws is broad-ranging, their effective use hinges on a blend of meticulous operation, adherence to safety norms, and understanding the tool’s capabilities. The juxtaposition of jigsaws and circular saws is not a competition, but rather a complementary set of functional advantages that, when combined, enhance a woodworker’s versatility and efficacy. Engaging with professionals can provide further insights and practical assistance. Investing in understanding the intricate dynamics of these tools not only broadens one’s woodworking repertoire but also underscores a commitment to maintaining a safe and efficient creative environment, a standard upheld by reputable providers like Brisbane Handyman Services.