Last Updated on December 1, 2023 by Pro Handyman Australia – Editorial Team

Understanding the Fundamentals of Circular Saws

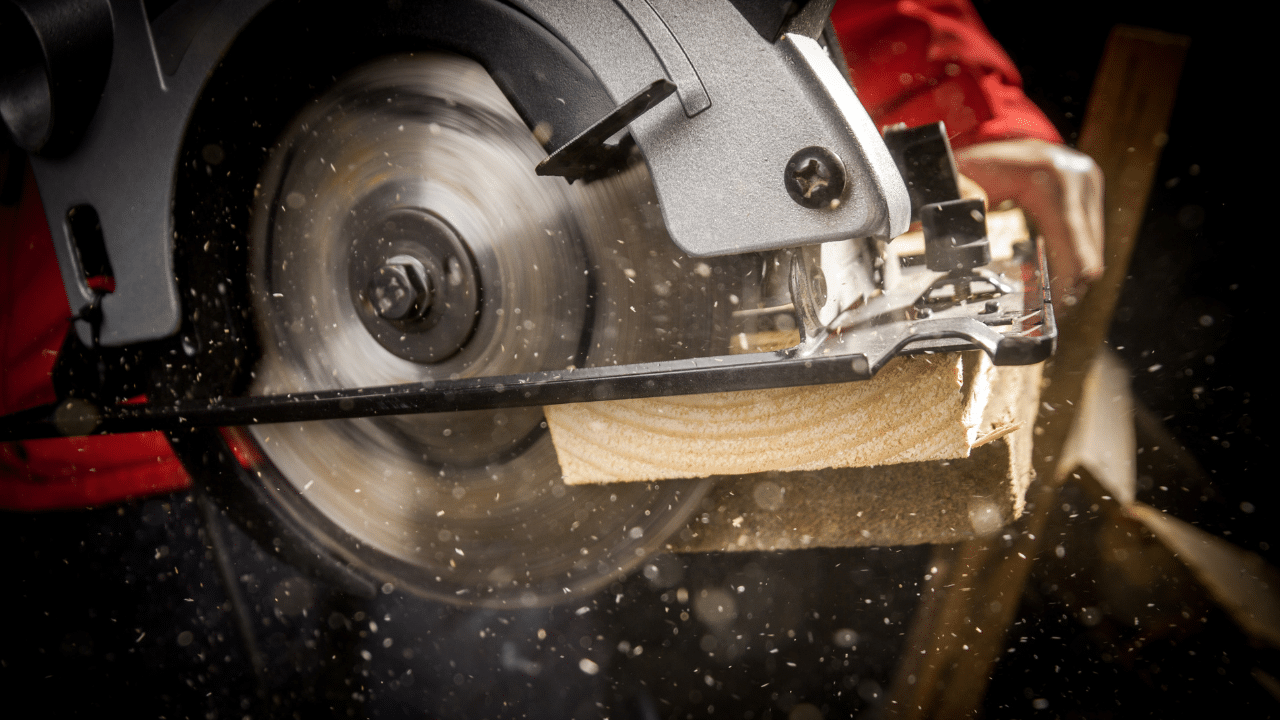

A circular saw, especially the best circular saw models, is a highly versatile power tool widely used in various fields. Its capacity to cut a broad spectrum of materials such as wood, steel, masonry, and ceramic tile is largely dependent on the type of blade used. Therefore, the selection of an appropriate blade is a critical step to achieve optimal results.

A circular saw allows for quick and straight cuts either across a board (crosscuts) or along its length (rip cuts). It can also be adjusted to create bevel cuts. Standard components in a circular saw include a blade guard for safety, a footplate for stability, and adjustable depth and bevel settings for versatility.

The size of a circular saw is typically denoted by the diameter of its blade. Common sizes range from 5-1/2 to 7-1/4 inches. It’s worth noting that many options are available for circular saws, thus your specific needs should guide your selection. For those in need of guidance or assistance with their circular saw needs, Handyman Services Melbourne offers expert advice and services to help you find the best circular saw for your project requirements.

Distinct Circular Saw Designs: Sidewinder and Worm Drive

Circular saws come primarily in two designs: sidewinder or inline saws, and worm drive saws.

Sidewinder or inline saws are the most traditional and prevalent. In these models, the motor aligns with the blade’s axis, and a direct shaft runs from the motor to drive the blade. These saws, being more compact and lightweight than their worm drive counterparts, are ideal for most circular saw applications.

On the other hand, worm drive saws feature motors positioned at a right angle to the saw blade. This arrangement uses gears to enhance the torque transferred to the blade, making these saws suitable for heavy-duty tasks. Despite being longer, worm drive saws tend to operate more quietly than sidewinder saws.

Evaluating Circular Saw Power Sources

Choosing the correct power source for your circular saw will largely depend on where and how you plan to use the tool.

Cordless circular saws offer convenience, especially in areas where using extension cords is challenging. These saws, being smaller than most corded versions, are advantageous in confined spaces. However, their cutting capacity is mostly restricted to wood and wood products due to battery limitations.

In contrast, corded circular saws offer more robust performance, making them suitable for tough cutting jobs such as masonry, steel, and continuous woodcutting. As they are not reliant on batteries for power, they offer greater longevity in operation. Ensure you have a compatible extension cord for these saws, following the manufacturer’s guidelines for safety.

Deciphering Circular Saw Features

Recognizing the various features of circular saws is crucial for safe and efficient operation.

Blade capacity, for instance, dictates the maximum depth of cut a saw can achieve. Larger blades lead to deeper cuts, with the most common blade diameter being 7-1/4 inches. As a rule, smaller circular saws are easier to control because of their lighter weight.

Electric brakes are another feature that enhances safety by reversing the electricity flow in the saw motor when the trigger is released, leading to a rapid halt of the blade.

Moreover, features like spindle or shaft locks can make blade changes easier by immobilizing the shaft and blade. Bevel capacity, bevel stops, and laser guides are additional features that can facilitate precise and versatile cuts.

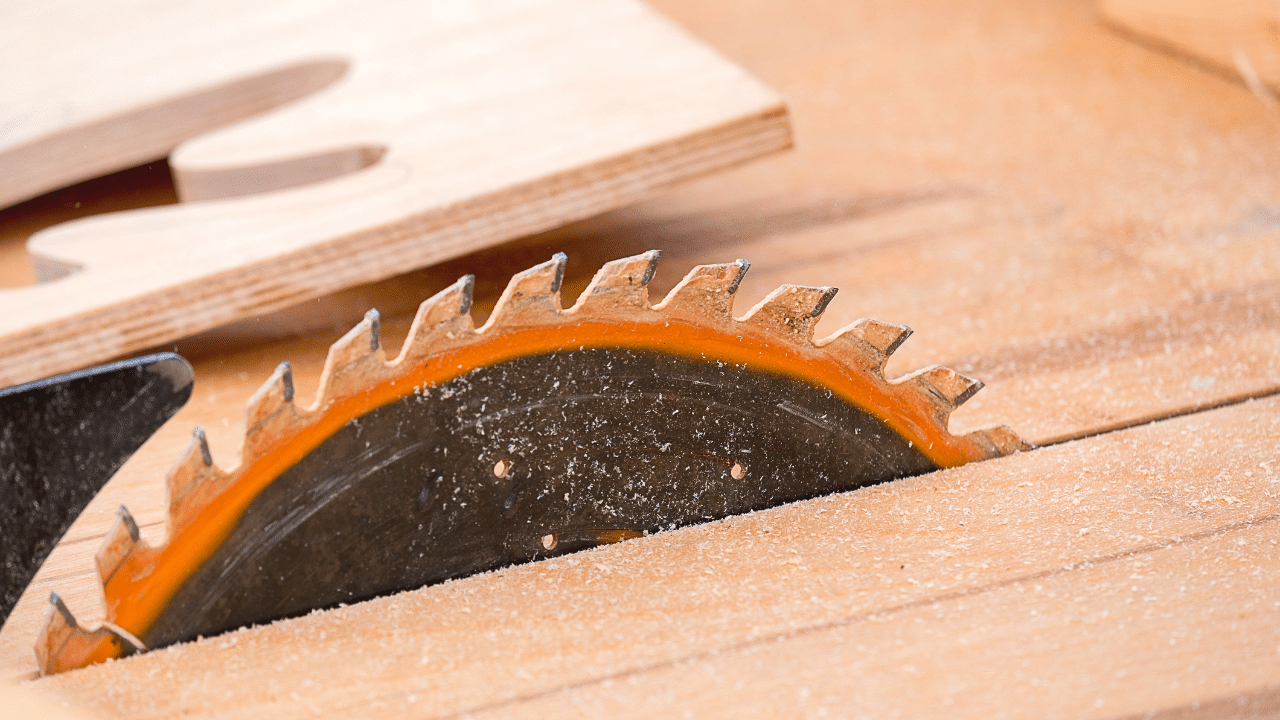

Understanding Circular Saw Blades

Handheld circular saws, table saws, and miter saws are prevalent tools for do-it-yourself enthusiasts, and knowing some key circular saw facts can be quite useful. They commonly utilize circular saw blades specially crafted for cutting wood or wood composites. Additionally, there are specialized blades available for cutting other materials like plastic, vinyl, and more. Other power tools that utilize circular blades include tile saws, concrete saws, chop saws, and grinders.

General Tips for Choosing Blades

While selecting the perfect blade for your power tool, you should pay attention to the following aspects:

The number of teeth on the blade affects the quality of the cut. Blades with fewer teeth cut at a quicker pace, but those with more teeth will yield a finer finish.

The gaps between the teeth, called gullets, play a vital role in chip removal. Deeper gullets often signify more aggressive teeth and facilitate faster cutting.

Expansion slots are integrated to deter warping as the blade heats and cools during usage. They also minimize vibration, ensuring a straighter cut.

Circular Saw Blade Applications

Below, you will find descriptions of various types of circular saw blades, focusing on their specific applications and features.

Rip-Cut Blades

Rip-cut blades excel in cutting along the grain of the wood, mainly when reducing the width of a board. These are suitable for wood, but may cause excessive splintering on plywood. Generally equipped with 16 to 40 teeth, they are designed for rapid and aggressive cutting. They possess deep gullets, contributing to efficient chip removal.

Crosscut Blades

Crosscut blades are formulated for cutting across the woodgrain, typically when trimming a board to a specific length. These blades are suitable for wood. Typically, they feature 40 to 80 teeth. They have smaller gullets compared to rip-cut blades. Although they don’t cut as quickly as rip-cut blades, they create cleaner edges.

Combination Blades

Combination blades serve as versatile tools, capable of making both rip cuts and crosscuts. These are suitable for wood. They contain multiple groupings of teeth, each group possessing one tooth for ripping and four for crosscutting. Deep gullets are integrated for effective chip removal.

Framing Blades

Framing blades are optimal for jobs demanding quick execution where the cut’s quality is less critical. Suitable for wood, particularly dimensional lumber. They are highly effective for rough carpentry. Generally, they come with 18 to 24 teeth.

Plywood Blades

These blades are exclusively fashioned for cutting plywood to the required dimensions. Suitable for plywood to minimize splintering. They generally consist of 100 teeth or more. Though they cut slower than some blades, they leave a more refined finish.

Demolition Blades

Demolition blades are used when speed and performance take precedence over a neat cut. Suitable for dimensional lumber and plywood. They have lower tooth counts, enabling fast and assertive cutting. Often, they are capable of cutting wood that is embedded with nails. They may have a narrow profile for more manageable cutting and reduced material waste.

Fine-Finish Blades

These blades are crafted for projects where the cut’s quality is paramount, such as cabinet building and joinery. Ideal for cutting wood, composite decking, melamine, plastic, and vinyl. Usually, they consist of 60 teeth or more. Often, they feature a narrow profile for easier cutting and less material waste compared to other blades.

Continuous-Rim Blades

Continuous-rim blades are a specialized variety of diamond-edged blades.

- These blades excel in cutting materials like tile and slate.

- Unlike standard circular saw blades, they do not feature teeth and gullets.

- Diamonds are adhered to the edge of the blade, contributing to their cutting efficiency.

- They deliver a notably clean finish.

- Variants are available for dry-cutting only, wet-cutting only, or for both applications.

Turbo-Rim Blades

Turbo-rim blades bear a resemblance to continuous-rim blades, both being diamond blades. However, they possess a serrated rim instead of the usual teeth and gullets.

- They are efficient for cutting tough materials like brick and concrete.

- While they cut more aggressively than continuous-rim blades, they don’t leave as clean a finish.

- Options are available for dry-cutting only or for both wet and dry applications.

Segmented Blades

Segmented blades, another diamond-edged variety, feature a rim partitioned by gullets akin to those on a standard blade.

- These blades are adept at cutting sturdy materials like brick and concrete.

- Of all diamond blade types, they boast the most aggressive cut.

- While they cut more swiftly than the other diamond blade types, they leave a rougher finish.

- They are available for dry-cutting only or for both wet and dry applications.

Abrasive Blades

Abrasive blades, although lacking teeth like diamond blades, cut using an abrasive material, such as aluminum oxide.

- They are effective at cutting materials like brick and concrete.

- Depending on the specific blade, they may also be suitable as metal-cutting circular saw blades.

Stacked Dado Blade Sets

Stacked dado blades, primarily designed for woodcutting, are specially crafted for usage on table saws or miter saws.

- These blades are exclusively for use on wood.

- The set comprises two circular saw blades as well as several chipper blades and shims.

- They are utilized to cut grooves (dados) in wood to accommodate another piece of wood, a common requirement for shelves in a bookcase.

- Different combinations of blades and shims facilitate the creation of grooves of varying widths.

Identifying the Right Circular Saw Blade for Your Power Saw

Each circular saw blade is meticulously designed to cut specific materials and match certain power saws. It’s crucial to ensure the blade you select aligns with the material you plan to cut and fits your saw. While your saw manual will offer valuable guidance on compatible blades, here are some handy tips for quick reference.

- Handheld circular saws generally accommodate blades with diameters ranging from 4-1/2 inches to 7-1/4 inches. The teeth on these blades are frequently tipped with carbide to extend their sharpness.

- Tile saws typically employ 7-inch or 10-inch diamond blades.

- Table saws and compound miter saws utilize blades with diameters of 8-1/4 inches or 10 inches, akin to those for handheld saws, and are often carbide-tipped.

- Miter saws are usually compatible with blades measuring 7-1/4-inch, 10-inch, or 12-inch, and these blades are generally carbide-tipped.

- Circular saw blades for metal, such as those employed on metal-cutting chop saws, which are also referred to as abrasive saws or cut-off saws, often use 14-inch aluminum oxide abrasive blades or carbide-tipped toothed blades.

Additionally, it’s important to verify the size of the arbor hole, or the hole at the center of the blade. This hole must correspond with the arbor or shaft on your saw. Some blades with a circular arbor hole include an insert that can be removed to fit saws with a diamond-shaped arbor.

Changing a Circular Saw Blade: A General Guide

While the steps to change a circular saw blade will differ depending on the type of tool, you should always consult your saw manual for specific instructions. Here are some general guidelines to follow when changing a blade on a handheld circular saw:

- Disconnect the tool from its power source, whether by unplugging it or removing the battery.

- Activate the blade lock button on the saw.

- Attach the included blade wrench to the head of the blade stud or arbor. You might need to use the wrench to rotate the blade slightly to allow the blade lock to fully engage.

- With the blade secured, turn the wrench counterclockwise to loosen and remove the stud and the outer blade washer.

- Carefully push the lower blade guard aside and extract the blade through the slot in the saw foot or base.

- Position the new blade to spin in the correct direction and slide it up through the slot and onto the blade shaft, resting against the inner blade washer.

- Ensure the outer washer is correctly positioned and install the blade stud. Hand-tighten the stud in a clockwise direction until it’s secure. Lock the blade and use the included wrench to tighten it slightly as per the manufacturer’s instructions (for example, 1/8 turn or to specific guide markings). Be careful not to overtighten.

Ensuring the Sharpness of Your Circular Saw Blade

When it comes to sharpening a circular saw blade, it’s advisable to engage the services of a professional. This is particularly relevant as sharpening some blades necessitates specialized tools that are not typically available in the average do-it-yourselfer’s toolkit. Trying to sharpen different types of circular saw blades independently carries the risk of causing damage to the blades.

To minimize the frequency of sharpening your blades, consider investing in carbide-tipped blades. While they command a higher price than other blade types, they offer a significant advantage: they maintain their sharpness for a considerably longer period than steel or high-speed steel blades.

Selecting the Ideal Circular Saw: Key Considerations

Corded or Cordless: Deciding based on Utility

Circular saws are typically available as both corded and cordless models. Traditionally, the corded models were the go-to choice for enduring, heavy-duty cutting tasks. However, with recent advancements in battery technology, cordless models have bridged the performance gap considerably. Nevertheless, for those who require only one circular saw, a corded model can provide more consistent power. On the other hand, if budget allows for two saws, a cordless model enhances work flexibility, especially in areas where plug-in outlets are not readily accessible.

Many tool manufacturers offer a range of power tools that utilize the same battery. If you have a collection of tools from a single manufacturer, opting for a cordless circular saw compatible with your existing batteries can be an economical choice.

Understanding Power Rating

The power of corded circular saws is typically expressed in amperage. Presently, 15-amp saws are considered the standard, while 10- or 12-amp saws are suitable for infrequent use. Given the minimal price difference and the potential long-term use, higher amperage is recommended as it offers greater cutting power.

In contrast, the power of cordless circular saws is measured by the battery voltage, with most modern models utilizing lithium-ion battery systems. While there is a variety of 18-volt saws, more powerful 20-volt versions are also available. Alongside the voltage, the amp-hour rating denotes the operational duration of the saw before the battery needs recharging, which typically ranges from around 5 to 9 hours.

Determining the Right Blade Size

The categorization of circular saws is often based on the blade diameter. For most DIYers, a 7 1/4 inch diameter is an ideal choice, as such saws can cut through materials over 3 inches thick and offer a wide range of blade choices for cutting different materials. In addition, there are 6 1/2-inch and 8 1/4-inch saws for lighter and heavier tasks, respectively.

For specialty tasks, smaller trim saws with blade diameters of about 4 1/4 or 4 1/2 inches are also available, mostly used for cutting thin materials such as paneling, although some are capable of cutting dimension lumber.

Ergonomic Factors

At first glance, most sidewinder circular saws may appear quite similar, barring color differences. However, upon closer inspection, significant differences emerge in the handling and usage. Thus, it’s essential to test these tools at your local supplier to ascertain their comfort levels. Consider whether the handle fits your hand comfortably, the balance and weight of the saw feel right, and whether the visibility of the blade and adjustment components is adequate.

Good balance and a well-shaped handle can significantly enhance comfort and efficiency, so these factors should not be overlooked.

Additional Functionalities for Enhanced Performance

A circular saw with sufficient power and a quality blade can deliver satisfactory cutting. However, for long-term satisfaction, consider additional features such as:

- A saw foot made from cast magnesium, offering better durability than pressed steel.

- A power brake for instant blade stopping.

- Preset bevel stops on the saw foot, with 22 1/2 and 45 degrees being most useful.

- A spindle lock for simpler blade changes.

- Built-in work lights for better visibility of the workpiece.

- Laser guidelines for accurate alignment while cutting.

Optimal Shopping Strategy for Circular Saws

It’s a common fact that circular saws are available in various retail locations such as home improvement stores, hardware shops, supercenters, and online marketplaces. However, the physical experience of shopping may provide a more informed decision when considering such a tool.

When shopping in-person, you can actually hold the circular saw to assess its weight, inspect the quality of its construction, and peruse the range of models and brands. This tangible interaction can be invaluable in ensuring you choose the saw that best fits your comfort and project needs.

Simultaneously, it’s worth exploring the online retail space. The virtual marketplaces not only offer a vast array of options, but they also allow for quick and easy price comparisons. Therefore, after your in-store visit, you can browse online to contrast and compare prices to secure the most affordable deal.

Conclusion

In conclusion, purchasing a circular saw is a significant investment. It’s not merely about getting the best price, but more importantly, about selecting the right tool that best suits your requirements and comfort levels. Therefore, take your time to research, compare, and ultimately choose the circular saw that will serve you well in your home projects. Remember, the right tool can significantly contribute to the success and enjoyment of your DIY endeavors.