Last Updated on November 28, 2023 by Pro Handyman Australia – Editorial Team

If you’re in the market for a drill, especially for challenging tasks like drilling into concrete or masonry, the hammer drill should be on top of your list. This buying guide will provide you with the essential knowledge about why the hammer drill is a preferred choice, how it works, and how it differs from other tools.

Why a Hammer Drill is Essential and Its Mechanics

The hammer drill, often complemented by the best drill attachments, is designed specifically for power-intensive tasks, especially in tough materials like concrete. Unlike other drills, the hammer drill has a unique mechanism: two opposing ridged discs that spin and collide, creating a potent hammering force. This ensures rapid and precise drilling, making it indispensable for heavy-duty tasks.

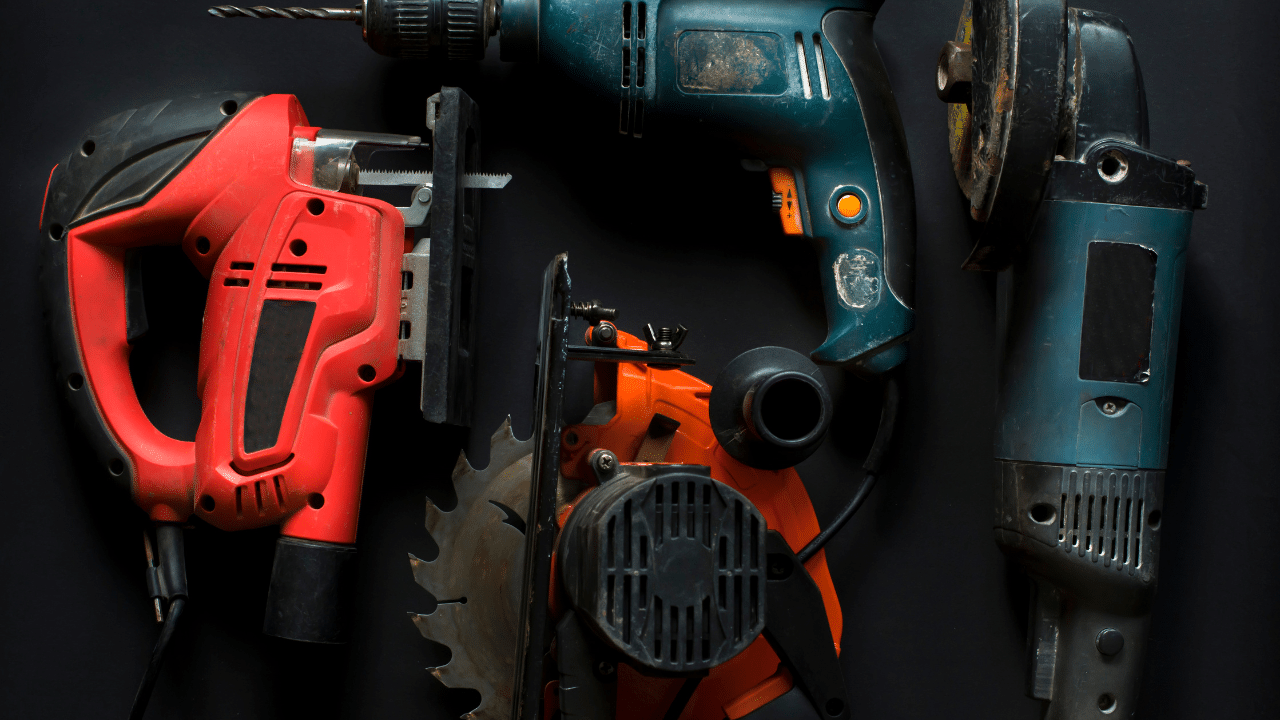

Distinguishing Features: Hammer Drill vs. Other Tools

When asking, “what is a hammer drill?” many might initially think that hammer drills look just like regular drills or impact drivers. However, when comparing rotary hammer vs hammer drill, they’re distinct in function. It’s crucial to note that while rotary hammers have a hammering feature, they aren’t the same as hammer drills. Understanding this distinction is paramount when deciding on the right tool for your needs.

Comparing Hammer Drills with Other Drills

Comparative Efficiency: Hammer Drill Vs. Standard Drills

Both hammer drills and regular drills have the ability to bore a hole into a concrete block using a masonry bit. However, when it comes to understanding how to drill into stucco, the efficiency levels between the two differ significantly. While a regular drill may eventually make a hole after considerable time and usage of multiple drill bits, a hammer drill accomplishes the task much quicker.

In the debate of screwdriver vs drill, especially when tackling robust surfaces, the distinction becomes crucial. When drilling into robust, decade-old concrete, a regular drill might struggle and may end up overheating or burning out. In contrast, a hammer drill will efficiently drill multiple holes throughout the day, thanks to the pounding force that makes it exceptionally adept at penetrating masonry.

Hammer Drills and Impact Drivers: Knowing the Difference

Impact drivers share a common feature with hammer drills – the hammering action that optimizes their functionality. However, the similarity ends there. Impact drivers are specifically designed for installing or removing nuts and bolts. On the other hand, hammer drills are tailored for drilling holes, which brings to mind the technique of how to drill into brick without a hammer drill. Hence, an impact driver cannot replace a hammer drill’s functionality and vice versa.

Hammer Drill or Rotary Hammer: Making the Right Choice

When searching for the right power tool for how to drill into bricks, you’re likely to come across rotary hammers. In many ways, rotary drills or rotary hammers share common features with hammer drills. Both are designed to drill into masonry and employ the hammer action mechanism to achieve their purpose. These tools look a lot like hammer drills, but there are some important differences to keep in mind.

Rotary hammers are fitted with a unique element that manages the impact. They incorporate an electropneumatic mechanism that delivers significant force during the impact, resulting in superior drilling efficiency in hard materials. Additionally, they can also be used for forging.

The primary parameter of a rotary hammer is the impact energy, expressed in joules, while the wattage is of lesser importance. Another distinction lies in the type of drill chuck used. Rotary hammers predominantly employ SDS Plus quick-change chucks. However, these chucks are not as adaptable as those used in hammer drills, because they require specific drill bits and chisels that work with the SDS Plus system.

Rotary hammers are also fitted with special safety clutches to protect your wrist from high torque forces during operation. Furthermore, these clutches also protect the tool from overload.

In essence, although hammer drills and rotary hammers share similarities and are often seen as variations of the same tool class, much like the track saw vs table saw comparison, they serve distinct, practical purposes in different work environments and tasks.

Hammering Down the Details: User Experience Stories

As you explore the various options in the hammer drill market, it becomes clear that understanding the different types of drills can enhance your purchasing decision. Real-life stories from users offer a unique perspective that technical specs alone can’t capture. In this context, we’ve gathered firsthand experiences with some popular hammer drill models, providing insights into the practical applications and performance of these essential tools among the different types of drills available.

Experience with the DeWalt DCD85MP2GT by Alex:

“Renovating my basement, I needed something powerful yet user-friendly. The DeWalt DCD85MP2GT was just that. Its ergonomic design made those long hours less strenuous, and it powered through both wood and masonry effortlessly.”

Feedback on the Bosch B-GBH36VEC-CP by Priya:

“My DIY patio project was a breeze with the Bosch B-GBH36VEC-CP. Its battery lasted longer than I had anticipated, and it felt robust yet manageable. A bit on the heavier side, but its performance makes up for it.”

These authentic user experiences underscore the importance of choosing the right tool for the job and provide a deeper understanding of each model’s real-world application.

Drill Down the Specs: In-depth Hammer Drill Comparisons

To help you make an informed decision, we’ve assembled a detailed comparison of some popular hammer drill models.

| Feature | DeWalt DCD85MP2GT | Bosch B-GBH36VEC-CP | Makita DHP451Z |

|---|---|---|---|

| Power (Watts) | 820 | 790 | 860 |

| Battery Life (hrs) | 7.5 | 9 | 7 |

| Weight (lbs) | 4.8 | 5.4 | 4.6 |

| Price ($) | 225 | 240 | 215 |

Analysis:

The Makita DHP451Z, though powerful, offers slightly less battery life, making the Bosch B-GBH36VEC-CP a compelling choice for projects requiring longer hours. DeWalt’s DCD85MP2GT remains a favorite, offering a harmonious blend of power and longevity at a competitive price.

For those keen on exploring even more nuanced comparisons and insights, we recommend diving into our article titled “The Best Hammer Drill Reviews & Comparisons”. This resource will equip you with a thorough understanding, guiding your next purchase seamlessly.

Distinguishing Between Types of Hammer Drills

Hammer drills and rotary hammers are the two primary types available in the market. While there’s a slight overlap between hammer drills and regular drills featuring a hammer function, rotary hammers distinctly stand out. They are designed explicitly for drilling or hammering into concrete and masonry.

These tools come in two main variations – corded electric models and cordless battery-powered versions. For those new to DIY or construction, understanding how to use a drill, especially when tackling hard concrete and masonry, is crucial. More potent hammer drills or rotary hammers are usually desirable for such tasks. These robust tools can withstand consistent usage even on challenging decade-old concrete, providing larger holes with more prominent drill bits.

In a typical construction environment, there’s a need to drill a multitude of holes at a speed that can wear out even the strongest regular drills. Hence, when it comes to hammer drills, a larger, more potent model often proves beneficial, provided it aligns with your budget.

Understanding Light-Duty Hammer Drills

Light-duty hammer drills, often resembling regular drills with a hammering action, are entry-level models usually priced at or under a hundred dollars. Their identifying feature is their motor power – most corded electric models feature motors ranging from 6 to 8 amps.

Several battery-powered hammer drills also belong to this category, although they tend to be priced higher. These drills can comfortably make holes up to half an inch wide in mortar and brick. They might struggle with tougher concrete, leading to a more prolonged drilling time per hole when used on hard, older concrete. Nonetheless, for woodworking and lighter masonry, these drills are sufficiently capable.

Getting to Know Heavy-Duty Hammer Drills

The heavy-duty hammer drills category begins to showcase tools with motors ranging from 7 to 10 amps. These drills can tackle light masonry and concrete, drilling holes up to 5/8 of an inch.

Higher-end models in this category begin to offer additional features, including multiple modes for hammering and drilling, making it easier to drill into concrete. This versatility allows the tool to handle various materials – masonry, wood, steel, and ceramic.

Key Features to Consider in Hammer Drills:

When selecting a hammer drill, consider the following features for enhanced performance and comfort:

- An assist handle on the side aids in precise, controlled drilling by offering a two-hand grip.

- A variable speed trigger provides speed control for the drill bit, enabling usage on materials beyond masonry and concrete, including wood.

- A two-finger trigger enhances comfort and offers improved control.

- Solid metal gear housing ensures job site durability and increased reliability.

- An adjustable side handle with depth gauge offers greater control and versatility, even in challenging-to-reach spots.

- A carrying case proves to be beneficial, especially for carrying a variety of bits with the tool.

- Built-in LED lighting illuminates the target area, ensuring you have clear visibility.

- Brushless EC motors offer enhanced efficiency, cooler operation, and potential for smart features like soft start or kickback control.

- A hammering switch allows the hammer function to be turned off, enabling the tool to be used as an ordinary drill.

Corded vs. Cordless Hammer Drills: Making the Right Choice

The pivotal factor that distinguishes corded hammer drills from their cordless counterparts is the requirement for an electrical outlet. Despite this requirement, corded hammer drills offer limitless operating time and generally feature larger and more robust electric motors. These attributes are particularly beneficial when working with power-intensive tools like hammer drills and rotary hammers, often used for drilling through concrete and masonry. As these tools consume a significant amount of energy, a corded hammer drill eliminates the need to pause for recharging. Furthermore, these drills are typically safe to use with an extension cord, extending their reach.

Corded drills often weigh less than their cordless counterparts due to the absence of a hefty battery pack. If you choose a mains-powered corded drill, you’ll likely need an extension lead. On the other hand, a cordless drill provides enhanced mobility, enabling you to operate freely without an extension cable trailing behind. However, the most potent cordless models typically command a higher price than their corded equivalents.

Conversely, cordless hammer drills offer enhanced convenience at the worksite without the obstruction of cords. These battery-operated models are particularly advantageous when drilling holes in concrete or masonry ceilings or beams. They also offer portability, making them suitable for work on ladders or scaffolding. High-quality batteries in these drills can store substantial charge, with a good 6 Ampere-hour (Ah) battery usually being sufficient for drilling over 200 holes in concrete.

When wondering how long cordless drill batteries last, it’s crucial to note that today’s cordless drills use rechargeable Lithium-ion batteries, which are highly efficient. This advancement allows the battery to reach full charge quickly—often in under 60 minutes—and retain power for longer. A bonus is that the same battery can power other tools from the same brand, so you can save money instead of buying multiple batteries.

Corded power drills are rated in watts, with basic models starting around 450 watts and robust hammer drills reaching approximately 1500 watts. A higher wattage is beneficial for drilling masonry, while a lower wattage is adequate for plasterboard. For most elementary home DIY tasks, a 550-watt drill is sufficient.

In contrast, cordless drill power is measured in volts. The voltage rating reflects the drill’s power, with battery sizes typically ranging from 12V to 20V.

Identifying Your Drilling Material

At some point, you’re likely to need to drill into masonry, and this is where understanding the types of bits for drills becomes crucial. Necessitating a drill with a hammer function, if your task involves drilling large-diameter holes in masonry, a corded drill with a low-speed gear is advisable. Furthermore, if you foresee drilling into various materials—such as wood, plastic, or metal—it’s crucial to be familiar with different types of drill bits, including the types of wood drill bits. A drill featuring a multiple-speed setting paired with the appropriate drill bit type for each material is a wise choice.

Considering a Screwdriving Function

If a screwdriving function is among your requirements, seek a drill that offers variable speed or torque control and has a reversible feature. This functionality enables the tool not only to drive in but also to remove screws, adding to its utility and versatility.

Delving into Rotary Hammer Drills

While rotary hammers tend to be heavier and costlier than ordinary drills, they are specifically designed for drilling holes into masonry and are equipped with SDS chuck attachments for this purpose. Furthermore, these tools often feature hammer-only modes, enabling the use of chisels and scrapers, thereby extending their utility.

Larger models of rotary hammer drills typically operate in hammer mode constantly, as they are designed for the most challenging tasks.

Crucial Features in Rotary Hammer Drills

When selecting a rotary hammer drill, consider these critical features to enhance performance and ensure user comfort:

- Vibration control features that include rubber mounting and foam padding help alleviate the strain on your hands, which is particularly important when using this substantial tool for extended periods.

- Forward and reverse rotation modes facilitate easy extraction from deep holes.

- The chisel function or combination hammer function halts bit rotation, enabling the use of various attachments, such as chisel bits, spade bits, or blunt nose bits, which are better suited for the hammering action.

- Kickback control automatically ceases motor operation if the bit becomes stuck in the material being drilled. This feature prevents the tool from being wrenched from your grip, though some may view this as a double-edged sword.

- Variable speed control allows you to adjust the rotation speed of your rotary hammer, often regulated by how deeply you press the trigger. Some models feature a lock switch to maintain the current rotation speed.

- Soft start or enhanced tool control gradually increases the RPM of the rotary hammer for better speed control, crucial when working with or near delicate materials.

- Dust extraction reduces the amount of dust and small pieces by collecting most of it in a built-in bag or sending it to a port where you can attach a vacuum cleaner.

Criteria for Comparing Hammer Drills

When comparing hammer drills, power is the initial consideration, just as understanding the various table saw uses is crucial when selecting the right table saw for woodworking. Dealing with robust masonry and concrete necessitates as much power as possible from your tool to complete the job efficiently. Moreover, the size of the hole you need to drill is another factor to consider. Larger holes may require larger bits, leading to a choice between smaller 3-jaw chuck bits and the more substantial SDS bits.

Understanding Power and Impact Power

For corded electric power tools, the hammer drill’s power is indicated by the main motor’s wattage rating. This metric is a general guide to the power of the hammer drill. The input power rating, however, is transformed into output power based on several factors, including the tool’s gearing and RPM.

Corded rotary hammers typically have ratings in amps, while cordless rotary hammers feature voltage ratings. The runtime for battery-operated models can be estimated from the battery’s capacity rating, typically given in ampere-hours (Ah).

As rotary hammers possess an impact piston hammer, their impact energy ratings are also critical. In this context, impact energy is provided in joules; the higher the figure, the more force the piston can exert on the chuck.

Assessing Speed and Hammering Speed

Rated speed, usually specified in rotations per minute (RPM), is another factor to examine. Hammer drills rotate at approximately the same speed as standard drills, achieving up to 3,500 RPM. Conversely, rotary hammer drills often operate more slowly, typically spinning at sub-1,500 RPM or even slower.

A similar pattern emerges concerning hammering speed. This speed is expressed as an impact rate in beats per minute (bpm). Typical rotary hammer drills can achieve impact rates up to 4,000 bpm or higher. In contrast, hammer drills tend to have considerably faster bpm rates, with mid-range hammer drills reaching 50,000 bpm or more.

Examining Drilling Depth

Drilling depth is a vital consideration when purchasing any drill, be it a standard drill, hammer drill, or rotary hammer. Manufacturers typically provide comprehensive estimates of their tools’ drilling range.

Drilling ranges are generally specified in millimeters (mm) for metric scales or inches (in.) for imperial scales. Maximum drilling diameters for masonry, wood, and metal are often given in the case of hammer drills.

Exploring the Various Types of Drills for Simple Tasks

With an array of drill types and parts of a drill available in the market, choosing the perfect one for your task may seem challenging. Here we break down the features of various drill types to help guide your decision.

If your primary need is drilling small holes in wood, plasterboard, and occasional masonry, a hammer-action drill would be an ideal choice. Opt for one with an 18V battery for cordless models or at least 550 watts for corded ones. A chuck size of 13mm should suffice as it accommodates a good range of drill bits, up to 13mm in diameter.

To assist you in discerning more from your potential drill, we have detailed the primary features of each drill type and their best-suited tasks.

Power Screwdrivers

These lightweight, cordless tools are perfect for all your domestic screwdriving needs. Their cordless nature makes them ideal for tightening screws in confined spaces and swiftly assembling flat-pack furniture. Due to their convenience and lighter weight than drill drivers, these tools are highly favored. They come equipped with forward and reverse settings for easy operation but do not have the ability to drill holes.

Drill Drivers

For a versatile option capable of handling minor tasks around your home, drill drivers are worth considering. These tools can make holes in wood and metal. They also work like screwdrivers, helping to remove and put in screws. They can do this with different drill and screwdriver parts. They are particularly handy for installing shelves, hanging pictures, and assembling flat-pack furniture.

Combi Drills

Combi drills offer all the features of a drill driver, along with an additional hammer-action capability. This makes them suitable for drilling into masonry and brick. The multipurpose functionality of these 3-in-1 drills makes them an excellent all-rounder choice.

Impact Drivers

Primarily a heavy-duty screwdriver, impact drivers are ideal for repetitive or extensive screw driving projects. When comparing a hammer drill vs impact driver, many people often ask what is a cordless impact driver used for. It’s essential to highlight that its impact mechanism reduces strain on the wrist by doing most of the hard work. These tools excel at tightening bolts and nuts and making holes in metal because of their strength. Impact drivers are a bit smaller and lighter than a drill driver.

Hammer Drills

Hammer drills, also called impact drills, are strong tools that can make holes in tough things like concrete and brick. They are ideal for heavier-duty tasks around the home, like installing shelves or securing gutters. They feature multiple torque settings, allowing you to adjust the power while keeping the RPM low. This ensures it can power through hard materials while limiting surface area damage. While not all hammer drills have a reverse screwdriving function, impact drills do.

SDS Hammer Drills

SDS drills share features with hammer drills but offer an enhanced hammer action with an SDS function (also known as Slotted Drive System). A hammer action in drills is driven by a part that pushes the drill bit forward and pulls it back. This makes the drill stronger and smoother. SDS drills use this method to easily make holes in very hard materials. These drills employ special SDS drill bits designed to prevent slippage and withstand the powerful force of their hammer action. As a result, they make light work of chiseling and chasing tasks.

Breakers & Demolition Drills

Breakers and demolition drills are tools used to break hard things like concrete, asphalt, bricks, and blocks. They hit the surface really hard and can also be used to make grooves in brickwork and to take off tiles.

Drill Technology Deciphered

A range of technology options can come into play when choosing your ideal drill. Understanding these technicalities can ensure your drill is more efficient, enduring, and environmentally friendly.

The Power of Lithium-Ion Batteries

Today, most cordless drills utilize Lithium-ion batteries. These are good for the environment, light to carry, and have more strength compared to older types of batteries.

A significant advantage of Lithium-ion batteries is their flexible charging capacity. You can recharge them irrespective of their current charge level. Moreover, they do not self-discharge, ensuring that a fully charged tool stored for a long time between DIY projects will be ready to use when needed.

In case you’ve opted for a cordless drill, having a spare battery could prove advantageous. It allows you to swap a drained battery with a charged one during extensive projects.

Brushless Motors: A Mark of Efficiency

A brushless motor implies the drill’s motor is constructed to minimize friction and heat build-up, resulting in enhanced torque control and swifter speeds. Selecting a drill with a brushless motor can extend the lifespan of the motor.

The Advantage of ‘Keep Cool Technology’

Some ranges of Lithium-ion battery-powered tools, such as the Erbauer range, feature ‘Keep Cool Technology.’ This technology ensures the battery cells remain cool and don’t overheat. As a result, the battery run time is extended, and the overall battery life increases.

The Versatility of One-Battery Tools

One+ battery tools power several tools from the same range, providing considerable flexibility. After you buy the battery and charger, you just need to buy the tool you need. This way, you can grow your collection of power tools.

When you encounter ‘bare tool’ in a product description, it implies that the tool comes without a battery. Having a single battery powering different tools can result in considerable savings on additional batteries and chargers. If you’re a frequent power tool user, it’s worth investing in a spare battery to keep your project moving seamlessly.

Delving Deeper into Hammer Drills

An interesting attribute of hammer drills is the drilling depth stop. This function allows you to determine the precise depth you wish to drill into the material. It proves particularly useful when you need to drill multiple holes of consistent depth, as the depth stop offers superior accuracy compared to manual control.

The Ideal Hammer Drill for Home Use

The perfect hammer drill will invariably depend on the user’s intended purpose. DIY enthusiasts and professional users will each have different requirements. Let’s first examine suitable options for home use.

If you anticipate using the drill regularly or infrequently, this can influence your choice. For most people, a drill is a tool for occasional tasks around the house, such as hanging pictures or undertaking simple garden construction work. In this context, one might wonder, “Can a hammer drill be used as a regular drill?” While hammer drills are designed for more robust tasks involving hard materials, they can indeed function as regular drills when their hammering action is disengaged. In such cases, a drill with a power rating of up to 650 watts should suffice. Opting for a more powerful drill that consumes more electricity might not be cost-effective if you only plan to use the tool infrequently.

The Best Impact Drill for Professional Use

For professional users, a more powerful hammer drill, potentially reaching 1000 watts, would be necessary. These robust tools are built to endure heavy loads and long hours of drilling into tough materials. It would also be beneficial to select a model with a wide range of speeds and an adjustable impact frequency. These features would make the drill versatile enough to handle a variety of materials encountered in professional work. Similarly, understanding how to use a circular saw is equally essential for professionals, as it offers the flexibility to cut through a variety of materials with precision and efficiency.

Conclusion

In conclusion, if you enjoy DIY projects or use tools for your job, understanding the technology, strength needs, and special features of different drills, along with knowledge about sawdust recycling, can really help you pick the right one. Take the time to consider how frequently you will use the drill, the type of materials you will be drilling into, your specific needs, and how you can incorporate sawdust recycling into your work routine to make an informed choice that matches your requirements and preferences.